Vacuum Casting Solutions

Experience unmatched quality and versatility with our urethane casting services. Specializing in custom formulations, we deliver durable, high-performance parts tailored to your unique specifications. From prototypes to production runs, trust our expertise to provide innovative solutions that exceed your expectations in various industries!

- Instant Quotes & DFM Feedback

- Production Grade Quality

- Parts as fast as 3 days

- All uploads are secure and confidential.

- Delivery Nationwide as Fast as 24 Hours

- Low-Volume Manufacturing

- Superior Quality Assurance

About the Urethane Casting Process

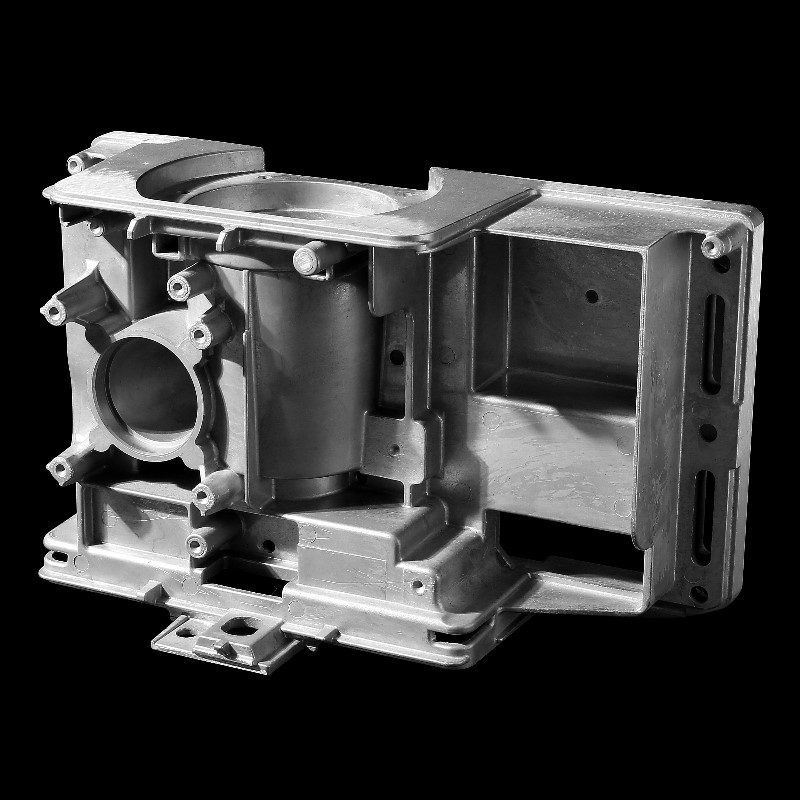

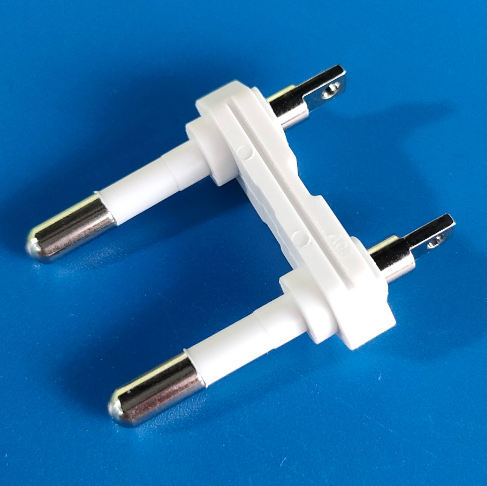

Urethane casting/Vacuum Casting or Polyurethane casting( also known as RTV molding, cast urethane, and silicone molding) is a fabrication method that uses silicone molds to produce production-quality plastic parts. At NPI, we have a massive range of plastic materials available, and we can cast parts as large and small, everything from headphones all the way up to 2m long car bumpers. This technique is ideal for creating prototypes to test your unique design.

Regarding tolerances, silicone molds can achieve approximately ±0.1 mm. After inspection and assembly, our vacuum casting services will produce additional silicone molds for more prototypes. Finished parts typically have a tolerance of ±0.15 mm. For vacuum casting parts exceeding 1000 mm in size, the tolerance can reach ±0.2 mm.

Urethane Casting Materials

Urethane cast parts are often compared to injection molding materials. For example, a tough urethane cast part may be described as an ABS-like, PC-like, or Nylon-like part. A soft and flexible material is described as “TPU-like or Rubber-like” . So our materials will be described like this.

Material

Picture

Description

Material Reference

Appearance

Soft-rubber-like

T0387,8400

PA-like

PX223

Black, Tawny

ABS-like

PMMA-like

PX 5210

Transparent

PP-like

UP 5690

White, Black

PC-like

PX520

White, Clear

*Note: Table values are indicative. Actual specs can differ based on printer model, material, and settings. Delivery times depend on order volume and processing needs. Contact us for tailored recommendations on printing processes and parameters.

Technical Specifications for Urethane Casting

- Description

- Dimensions

Lead Time

Up to 50 parts in 10 days or less, depending on the part complexity and quantity.

Accuracy

±0.15mm/100mm, with the highest precision up to ±0.05 mm.

Maximum Part Dimensions

The vacuum chamber’s dimensions (1900 x 900 x 750 mm) and the product’s maximum volume (10 liters) determine the mold’s size limitation.

Wall Thickness

A minimum wall thickness of 0.75 mm is necessary for filling the mold properly. A wall thickness of 1.5mm~2.5mm is recommended.

Service Life of the Silicone Mold

Typical quantities are up to 20-25 copies per mold (depending on the casting materials and the mold’s complexity).

Surface Finish & Textures

Textured, colored, painted, coated, clear polished, insert, and over-molding can be obtained. Custom finishes are available for request.

Prototype and Parts Made Easy - Worldwide Delivery & Any Order Size

With many years of manufacturing experience, NPI offers the best solutions for all rapid prototyping and low to large volume manufacturing needs. We streamline the innovation cycle into four simple but effective steps.

01

Upload Your Design

02

Receive Design Analysis

03

Start Manufacruting

04

Receive Your Parts

8 Steps to Create Custom Vacuum Casting Parts

Discover how we craft custom vacuum casting parts with our streamlined 8-step process:

- Master Pattern Creation: Createmaster pattern using 3D printing or CNC machining to precisely replicate your design.

- Silicone Mold Construction: Next, create a durable silicone mold by enclosing the master pattern in liquid silicone rubber.

- Casting Material Preparation: prepare the material by mixing a two-part polyurethane resin or other casting material according to the manufacturer’s instructions. The resin is then poured into a mixing container.

- Vacuum Degassing: The mixed resin is placed in a vacuum chamber to remove air bubbles, ensuring a smooth, high-quality finish in the final part.

- Material Pouring: The degassed resin is carefully poured into the silicone mold through a designated opening.

- Curing: The filled mold is then lefe to cure for several hours, allowing the material to set and achieve its full strength.

- Part Demolding: After curing, carefully remove the part from the silicone mold, which can be reused for multiple casts (approximately 20-25 times).

- Finishing Touches: The final step involves trimming or sanding the part to eliminate any excess material or imperfections.

This efficient process allows us to deliver high-quality, custom vacuum casting parts tailored to your needs.

Surface Finishes for Urethane Cast Parts

Precision Vacuum Casting for Diverse Industries

Vacuum Casting FAQs

- Draft angles for easy demolding

- Wall thickness (generally between 2-5 mm)

- Reduced undercuts

- Fillets and radii to improve mold strength and finish

Looking for Online Vacuum Casting Services?

- All uploads are secure and confidential.