Fully certified and accredited Sheet metal fabrication

We are globally recognized partner for China based sheet metal fabrication. Our expertise is in balance between quality and cost, we boast an impressive project portfolio.

- Your Assurance of Quality

- Parts in 24 Hours or Less

- Exceptional Parts, Unwavering Standards

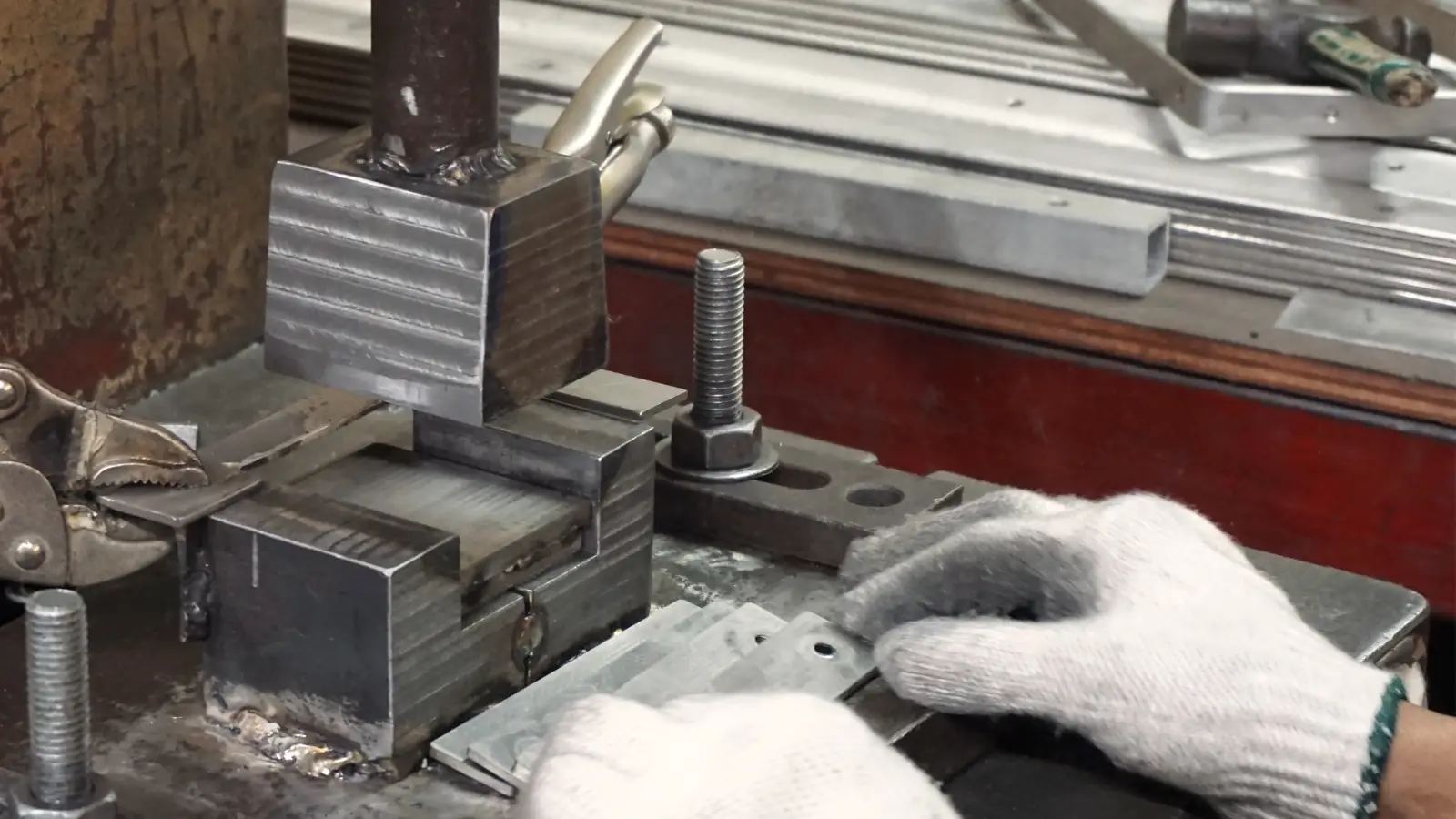

Sheet Metal Fabrication Services for Custom Parts

Out staff has a wealth of experience of working with a variety of metals grades and boasts an impressive project portfolio. All fabrication work is designed and manufactured to suit individual customer requirements and we have access to large stocks via our diverse supplier chain in order to meet urgent deliveries.

Our skilled team of professionals utilizes cutting-edge CNC and laser technology, combined with extensive fabrication expertise, to effectively address the unique requirements of each client. From initial design through to final production, we pursue excellence in every facet of our work, setting a benchmark for quality and service in the sheet metal fabrication industry.

Laser Cutting

The metal sheet is cut after being heated by the laser beam, and the metal prototype is cut quickly, making it one of the indispensable processes in the sheet metal manufacturing process.

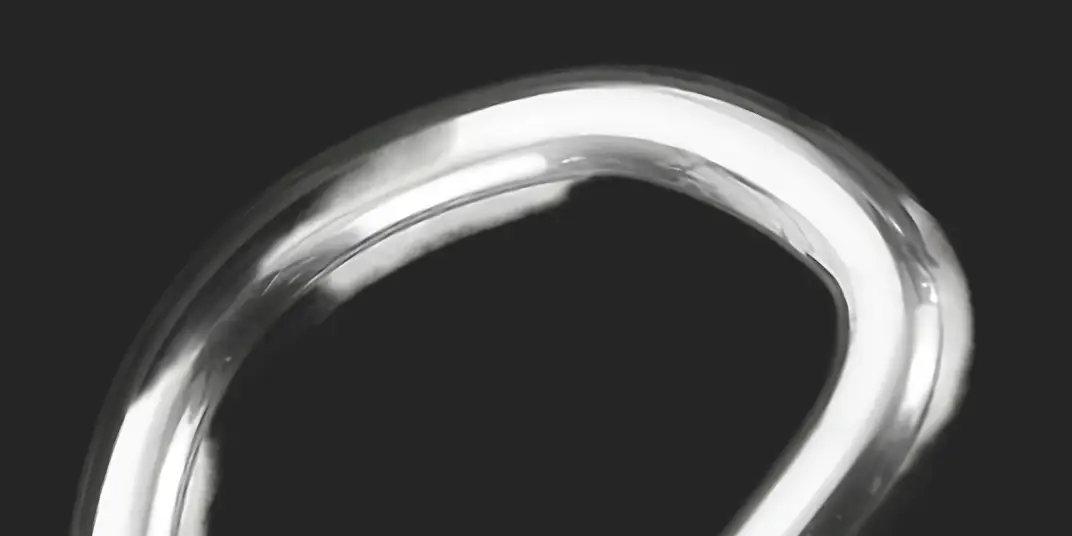

Bending

Bending is a widely used sheet metal fabrication process that creates V, U, and channel shapes along a straight axis. Bending is ideal for producing lightweight, high-quality parts for automotive panels, electrical enclosures, and storage units, making it a cost-effective choice for low to medium production volumes.

Stamping

Press the metal sheet and use the stamping die to perform blanking, embossing, bending, flanging, and coining, so as to obtain the required customized stamping parts.

Welding

Connect a variety of metal materials by means of high temperature or pressure to obtain a complete assembled sheet metal part. Usually used in pipelines, steel structures, metal cabinets, enclosures, etc.

Punching

Utilizing advanced CNC turret press equipment with 33 -250 tons of punching force, we can process mild steel, stainless steel, aluminum, brass, and copper sheets up to 4′ x 10′ and thicknesses ranging from .024″ to .25″, ensuring tolerances of ± 0.005.

Riveting

Riveting is a reliable fastening technique that joins metal parts without welding. It involves inserting and deforming rivets to assemble complex structures where welding is impractical.

Surface Finishing Options for Metal Sheets

Enhance the durability and aesthetic of your custom metal parts with our variety of surface finishing options. For finishes not listed on our quote page, simply select “Other” and specify your requirements for a customized solution.

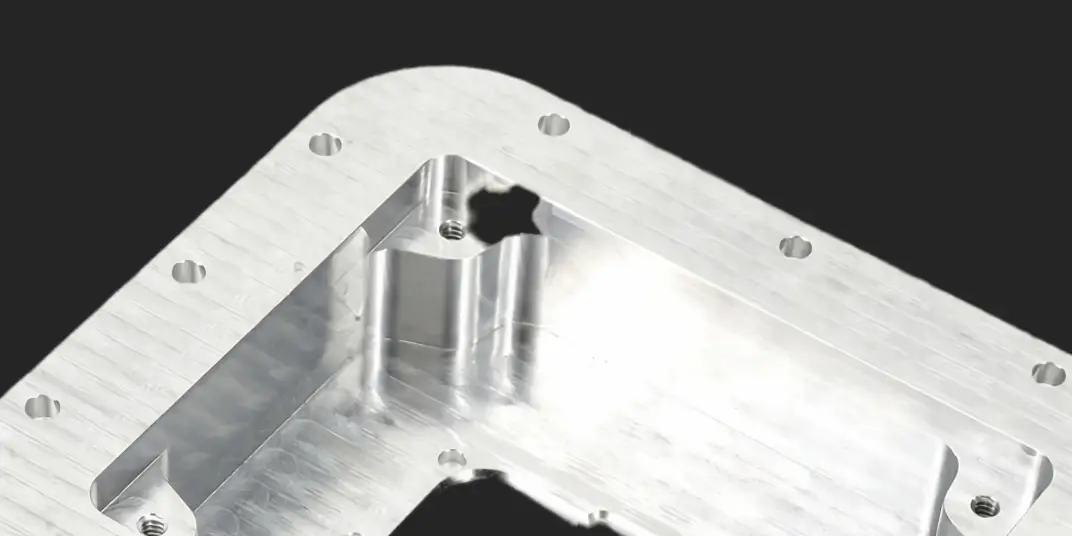

As Machined

As machined finish leaves the surface straight from the CNC machine, providing a cost-effective option with tool marks.

Anodizing

Anodizing increases corrosion resistance and wear properties, while allowing for color dyeing, ideal for aluminum parts.

Polishing

Polishing achieves a high gloss finish, reducing surface roughness and enhancing the aesthetic appeal of metals.

Sand Blasting

Sand blasting uses pressurized sand or other media to clean and texture the surface, creating a uniform, matte finish.

Tumbling

Tumbling smooths and polishes small parts by friction and abrasion in a barrel, offering a consistent but slightly textured finish.

Electropolish

Electropolish is a chemical process that smooths and brightens surfaces while improving corrosion resistance.

Alodine

Alodine coating provides corrosion protection and improves paint adhesion, mainly used on aluminum surfaces.

Heat Treatment

Heat treatment alters the mechanical properties of metal to increase its hardness, strength, or ductility.

Brushed Finish

A brushed finish creates a unidirectional satin texture, reducing the visibility of marks and scratches on the surface.

Powder Coating

Powder coating applies a thick, wear-resistant layer with excellent color and texture options, suitable for a variety of surfaces.

Electroplating

Electroplating bonds a thin metal layer onto parts, improving wear resistance, corrosion resistance, and surface conductivity.

Black Oxidize

Black oxidize is a conversion coating for ferrous metals that improves corrosion resistance and minimizes light reflection.

Prototype and Parts Made Easy - Worldwide Delivery & Any Order Size

With many years of manufacturing experience, NPI offers the best solutions for all rapid prototyping and low to large volume manufacturing needs. We streamline the innovation cycle into four simple but effective steps.

01

Upload Your Design

02

Receive Design Analysis

03

Start Manufacruting

04

Receive Your Parts

Advantages of Sheet Metal Prototyping

- Cost-effectiveness. Sheet metal fabrication is cheaper and faster than CNC processing. For example, many housings in the audio industry used to be CNC processed, but now they are more sheet metal fabrication.

- Multiple processing technologies. All surface finishing, oxidation, electroplating, powder coating, etc., can be done.

- Flexibility. Sheet metal fabrication is suitable for parts with complex shapes and generates less waste during production.

- High precision. Sheet metal fabrication service ensures product consistency. High dimensional accuracy, good interchangeability, and good surface quality.

- Fast production cycle. After the order is placed, we can deliver within a week.

Sheet Metal Fabrication for Diverse Industries

Custom Any Sheet Metal

Parts for Your Project

NPI has full capabilities in customizing any sheet metal parts through our fabrication services. We can manufacture according to your specific designs, shapes, sizes, surface finishes, thicknesses, and more. Our engineers can customize your orders through the following services and processes:

- We use laser cutting for easy and precise sheet metal cutting.

- NPI uses punching techniques for forming perforations such as countersinks, ribs, etc.

- We offer to bend or folding process by using press brakes.

- NPI uses different welding techniques such as spot welding, TIG welding, etc.

Aside from that, NPI is also an expert in sheet metal assembly, burning, hole punching, drilling, shearing, and more.

Sheet Metal Fabrication FAQs

Looking for Online Sheet Metal Fabrication Services?

- All uploads are secure and confidential.