The process characteristics of CNC milling are mainly reflected in the following aspects:

1. High precision and consistency

High precision: CNC milling can achieve very high machining accuracy by precisely controlling the motion path and cutting parameters of the tool through the computer. The pulse equivalent of the numerical control device is generally 0.001mm, and the high-precision numerical control system can even reach 0.1μm, meeting the high requirements for the size, shape and position of the part.

Consistency: CNC milling avoids the operator’s operational errors, ensures the dimensional identity of the same batch of machined parts, and greatly improves the consistency and stability of product quality.

2. High efficiency and automation

High efficiency: CNC milling machines are usually equipped with high-speed spindles and efficient feed systems, which can greatly improve processing efficiency. At the same time, CNC milling can realize the automatic tool change of a variety of tools, reduce the tool change time and improve production efficiency.

High automation: CNC milling machine has a high degree of automation and can achieve automated processing and unmanned production. The operator only needs to set the program, and the machine tool can automatically process, which greatly reduces the labor intensity.

3. Flexibility and adaptability

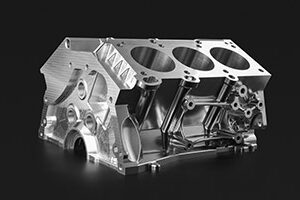

Flexibility: CNC milling machines can process a variety of complex shapes and structures of parts, including planes, surfaces, holes, slots and so on. By modifying the program, CNC milling can easily adapt to the processing needs of different parts.

Adaptability: CNC milling is not only suitable for the processing of metal materials, but also for the processing of non-metallic materials and composite materials. At the same time, CNC milling can handle parts that need to be processed in multiple processes after a clamping position, such as multi-process processing of box parts.

4. Wide processing range

CNC milling can complete drilling, boring, reaming, plane milling, bevel milling, groove milling, surface milling (CAM), tapping and other processing tasks, with a wide range of processing.

5. Good surface quality

CNC milling can precisely control the feed speed and cutting parameters of the tool, so as to obtain a good surface finish. This is essential to improve the appearance quality and performance of parts.

6. Save resources and protect the environment

CNC milling can precisely control the amount of cutting as needed, reducing the generation of cutting forces and cutting heat, thereby reducing energy consumption and environmental pollution.

7. Feedback and adjustment

CNC milling machines are often equipped with advanced sensors and control systems that monitor the process in real time and adjust it as needed. This ensures the stability and reliability of the process.

In summary, the process characteristics of CNC milling are mainly reflected in high precision and consistency, high efficiency and automation, flexibility and adaptability, a wide range of processing, good surface quality, resource saving and environmental protection, and real-time feedback and adjustment. These characteristics make CNC milling play an increasingly important role in modern manufacturing industry.