Medical Prototyping & Manufacturing

Leverage our advanced technology and skilled technicians to streamline your medical product development. From rapid prototyping to mass production, we deliver superior quality at competitive prices. Our expertise in medical device manufacturing ensures precision, efficiency, and regulatory compliance. Trust us to optimize your designs, select the best processes, and accelerate time-to-market.

- Innovation-Driven Clinical Excellence

- Committed to Precision

- Performance-Enhancing Advanced Materials

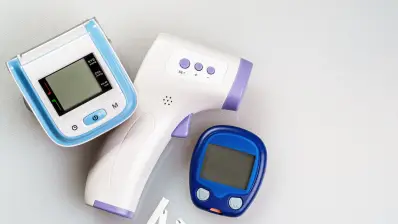

Expertise in Medical Device Contract Manufacturing

Our comprehensive manufacturing capabilities enable us to produce a wide range of medical device components and prototypes, catering to diverse healthcare applications. These include parts designed for direct patient contact and those used in medical equipment and machinery. Our solutions meet stringent industry standards, ensuring safety, reliability, and precision.

Prototyping and production for Medical Industry

We have extensive manufacturing experience and can produce related ancillary products for the medical industry and can bring your products to market faster.

- Free & Automatic DFM feedback

- Fastest lead time: 1 day

- Free consultant from experienced engineers

Our comprehensive manufacturing capabilities enable us to produce a wide range of medical device components and prototypes, catering to diverse healthcare applications. These include parts designed for direct patient contact and those used in medical equipment and machinery. Our solutions meet stringent industry standards, ensuring safety, reliability, and precision. Some of the applications include:

- Handheld devices

- Surgical instruments

- Medical testing devices

- Medical delivery systems

The medical and healthcare industry requires a broad range of parts and prototypes made from a range of materials. These include parts that are expected to make contact with the human body and those that are used in machinery and equipment used by medical professionals. Typical requirements include:

- Tight tolerances for critical parts and assemblies

- Materials that are biocompatible, non-toxic, or sterilizable

- Quality control via on-machine inspection and/or CMM

Below are some of the types of medical parts we can manufacture for you:

- Handheld devices

- Surgical instruments

- Medical testing devices

- Medical delivery systems

- Ventilators

- Implantable prototypes

- Prosthetic components

- Microfluidics

- UV sanitation components

- Prototypes

- Anatomical models

- Replacement parts

- Surgical instruments

- MRI and X-Ray components

- Monitoring equipment components

- Tables and panels

- Medical carts

- Physiotherapy apparatuses

- Electronic equipment components

- Prostheses

- Medical delivery systems

- Fluid management systems

- Biotechnology components

- Respiratory devices

- Handheld devices

- Diagnosis equipment

- Ultrasonic equipment

Common Materials for Medical prototypes

Titanium

High-strength internal joint and skeletal substitutes. Titanium is strong, temperature resistant, 3D printable, lightweight and corrosion resistant.

Stainless steel and Inconel

Various alloys of steel being their temperature resistance, strength and corrosion resistance. Ideal for swiss-type surgical equipment.

Medical-grade silicone rubber, TPE

Used in the manufacture of custom fittings and seals. These materials have laudable electrical, chemical and thermal resistance. They are bio-compatible, making them suitable for applications that may involve skin contact.

POM, PEEK, PEI

PEEK is a heat-sterilizable material that can be used as high-performance plastic. PEEK, POM and PEI are all suitable for use as joint replacements. They are high temperature and creep resistant, and sterilizable.

Nylon and ABS

Excellent for use in medical appliances. These materials are 3D-printable and very affordable.