Enhancing Innovation and Competitiveness in Consumer Products

Rapid prototyping and on-demand production enable consumer product companies to innovate their products swiftly, meet market needs efficiently, lower costs, and deliver tailored products, enhancing competitiveness and customer satisfaction in the dynamic consumer goods sector.

- Exceptional Precision in Manufacturing

- Safeguarding Intellectual Property

- High-Performance Advanced Materials

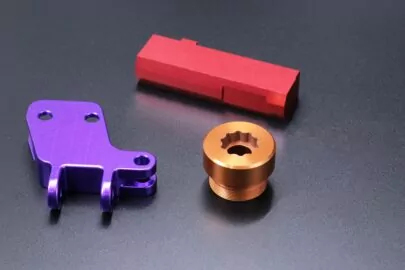

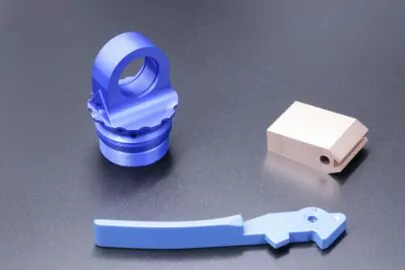

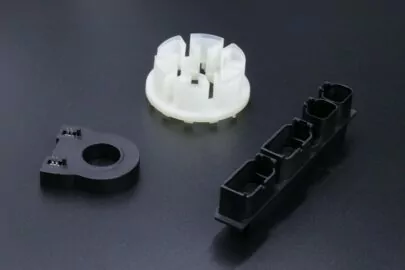

Applications of Consumer Parts

In today’s market, personalized consumer products are essential. NPI offers custom designs and unique material options, providing a competitive edge through innovative manufacturing. Our advanced capabilities can transform your ideas into reality for various applications. Experience the future of tailored manufacturing with us and elevate your brand’s uniqueness today!

- Electronic devices housing

- Personal wellness products

- Athletics and sporting equipment

- Cookware products

- Wearable devices

- Accessory components

- Virtual reality products

- Home Furnishings

- Smart home products

- Kitchen appliance

- Furniture Hardware

- Brackets and mounts Knobs

- Smartphone cases

- Internal mechanisms parts

- Custom knobs and handles

- Lenses and Covers

- Switches and Buttons

- Handles and Fixtures

- Enclosures and Panels

- Heatsinks and Hardware

- Beauty Tech Products

- Pet Tech Products

We Help From

Prototyping to Production

01 Prototyping

Our advanced rapid prototyping services provide an efficient and cost-effective way to create models for rapid testing. At this stage, we offer flexible prototyping solutions to match your specific requirements. By utilizing cost-effective materials and production methods, we bring your near-final product designs to reality.

- Low-volume prototyping and short-term production support

- Rapid tooling for accelerated design cycles

- Functional prototypes for concept modeling

- Quick concept validation

02 Engineering Validation and Testing

Confirm that every performance aspect is met with functional prototypes that accurately represent your final product concept. At this stage, our team of experienced engineers and technicians use advanced techniques and equipment to test and validate your products to the highest standards. We provide comprehensive test reports, detailing the results and performance of your products.

- High-quality design options

- Optimized material properties for custom design

- High-resolution functional prototypes

03 Design Validation and Testing

Evaluate the performance, functionality, and aesthetics of your medical product with precision. SRapidDirect uses the latest technologies to validate and test your product designs to ensure they meet your specifications and function as intended. With many designs, materials, and finishes, we can create consumer goods with end-use functionalities that are ideal for market and consumer testing.

- Validate materials and surface finishing

- High-quality parts with end-use functionalities

- Production-grade life cycle testing

04 Production Validation and Testing

Prepare designs for large-scale manufacturing with cutting-edge production capabilities and a rigorous quality management system. Achieve production targets through feedback on your design from the DVT stage. Enhance the efficacy of manufacturing by making final modifications to your model. At this phase, we’ll work with you to determine the most appropriate methods and establish the supply chain.

- Verify yield and functionality of production-grade parts

- Precision parts with tight tolerances

- Low-volume production of fully functional parts

05 Mass Production

Effortlessly transition from product evaluation to large-scale production of end-use components. Take advantage of stringent quality standards and prompt delivery of finished goods. We have the expertise and capabilities to handle the mass production of your consumer products.

- Custom fixturing and tooling for the manufacturing line

- Precision machined parts with tight tolerances

- Secondary operations for complete products

- Extensive quality management plans

Consumer Products FAQs

Prototyping allows designers and engineers to visualize and test ideas, identify design flaws, gather user feedback, and reduce product development costs and risks.

Common materials include plastics (e.g., ABS, Acylic, PC), metals (e.g., aluminum, stainless steel), and composites (e.g., carbon fiber). The choice depends on the function and aesthetics required.

Technologies include 3D printing, CNC machining, silicone molding and sheet metal fabrication etc. Each method has its own advantages based on precision, material, and cost.

There are several types of prototypes used in consumer product development:

Low-Fidelity Prototypes: These are basic representations of a product, often made from paper or cardboard. They are useful for initial brainstorming sessions and gathering early feedback.

High-Fidelity Prototypes: These prototypes closely resemble the final product in terms of appearance and functionality. They may be created using advanced materials and technologies such as 3D printing.

Functional Prototypes: These models focus on testing specific functionalities or features rather than aesthetics. They help assess performance under real-world conditions.

Visual Prototypes: These emphasize the look and feel of a product without necessarily functioning like the final version. They are often used for marketing purposes or stakeholder presentations.

The choice of materials for prototyping varies based on the type of prototype being developed:

Foam Board/Cardboard: Commonly used for low-fidelity prototypes due to their ease of manipulation.

Plastic (e.g., ABS, PLA): Frequently utilized in 3D printing high-fidelity prototypes because they can mimic the properties of final products.

Silicone/Rubber: Often used for functional prototypes where flexibility and durability are needed.

Metal Components: Sometimes incorporated into high-fidelity prototypes to test mechanical functions accurately.

At NPI, we take the confidentiality of client designs and intellectual property very seriously. We have strict non-disclosure agreements (NDAs) in place and follow industry best practices for data security and privacy protection.

Consider factors like the product’s intended use, mechanical properties, thermal properties, and aesthetic requirements. Or just consult us directly, our expertise can help you find the most suitable material.