Custom EDM Services Online

Get precision wire EDM parts with accuracy and intricacy. Ideal for complex geometries that demand the highest standards.

- ISO 9001:2015 Certified

- Tight tolerances +/- .0001" (.0025mm)

- Sink EDM & Wire EDM & Small Hole EDM

- 100% Quality Guaranteed

- Consistently Ensuring Precise Specifications

- Guaranteed Quick Delivery Times

- Comprehensive and Rigorous Checks

Wire Electrical Discharge Machining (EDM) Services at NPI

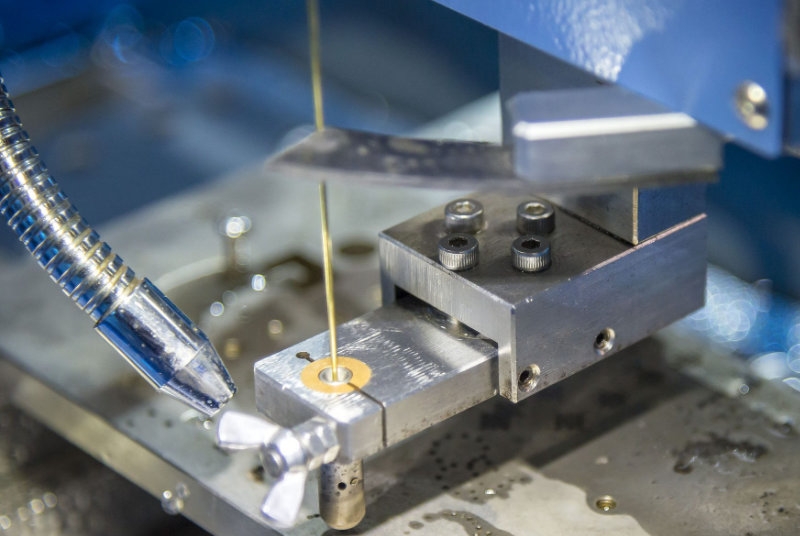

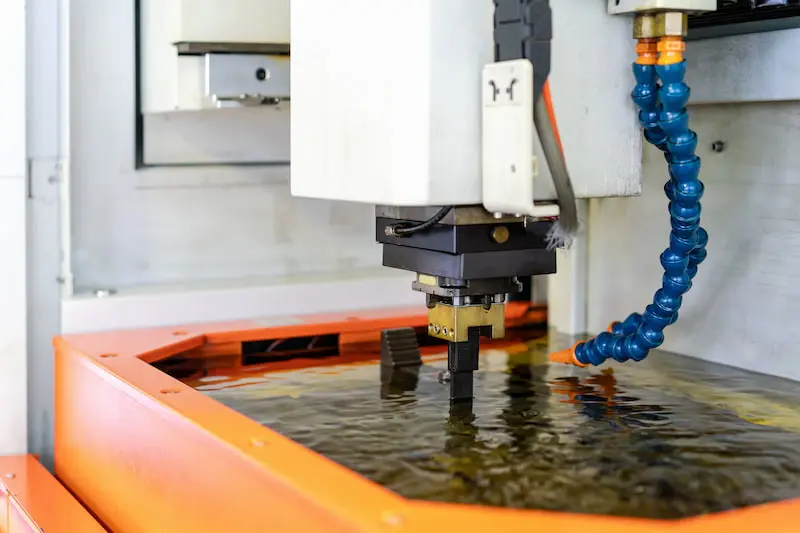

At NPI , we harness the cutting-edge technology of Wire Electrical Discharge Machining (EDM) to produce precision-engineered parts for our clients across various industries. Wire EDM is a specialized machining process that employs high-frequency electrical sparks to shape and detail conductive materials with exceptional accuracy. By creating a controlled electrical discharge between two electrodes submerged in dielectric fluid, this process melts and vaporizes the material, allowing for intricate cuts and designs.

The true strength of wire EDM lies in its ability to machine complex contours and fine details in materials that are often difficult to process using traditional CNC machining methods. Our wire EDM technology excels with challenging materials such as heat-treated steels, superalloys, and specialty metals. With this advanced technique, we achieve parts with incredibly tight tolerances and intricate features, including narrow slots and small holes, all with unmatched precision.

We are dedicated to providing top-tier wire EDM machining services. Our advanced wire EDM equipment, combined with our team of skilled technicians who are experts in their field, ensures that we meet the rigorous demands of any industry. This combination solidifies our position as a leader in wire EDM machining, capable of delivering parts that exceed expectations and drive innovation.

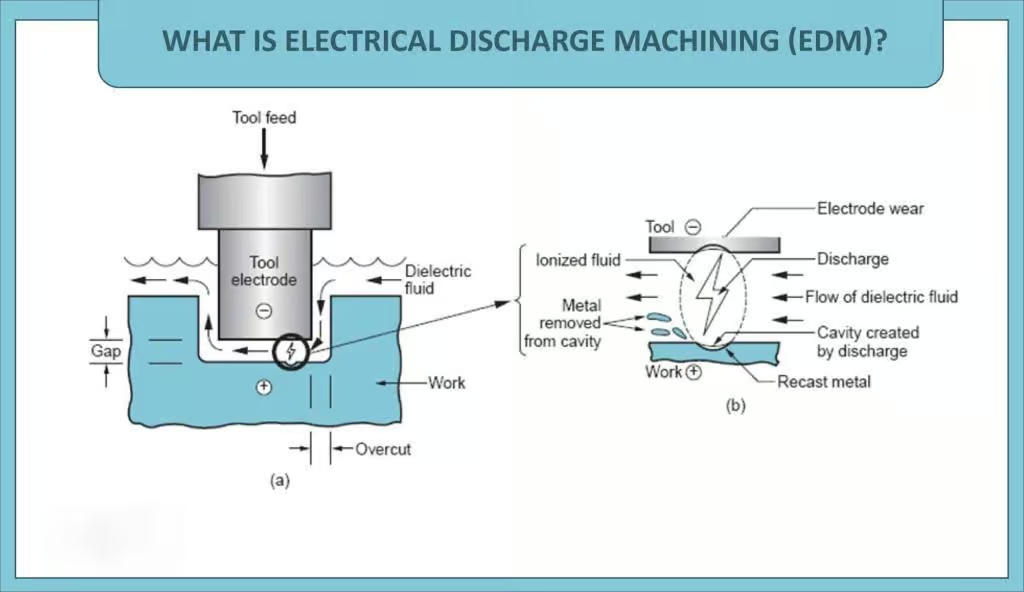

What is Electrical Discharge Machining?

EDM (Electrical Discharge Machining) is a non-contact machining method that does not apply stress to the workpiece. It is used to cut unmachinable complex shapes and cavities using electrodes on very hard and difficult-to-machine metal materials. The process involves electrodes and workpieces, both submerged in a dielectric fluid (usually paraffin or kerosene). Electric current flows between the workpiece and the electrode, repeatedly creating tiny plasma zones that instantly melt and remove material.

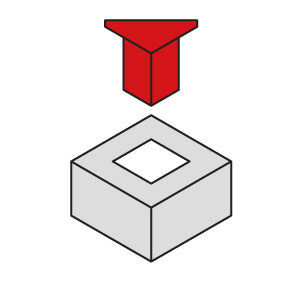

Sink EDM

he sinker discharge EDM process allows complex electrode shapes to be used to create equally complex cavities. Graphite or copper electrodes are pre-machined to the desired shape and then sunk into the workpiece by etching to form holes that are the opposite shape of the electrode.

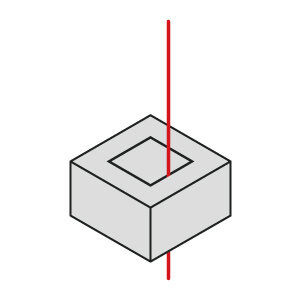

Wire EDM

The wire-cut EDM process is an alternative to sinker machining and works similarly to how a chainsaw cuts wood. Using a piece of metal wire (made of copper or brass), the wire cuts away excess material from the workpiece through a high voltage discharge.

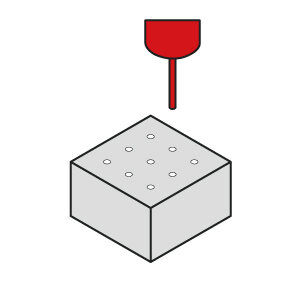

Small Hole EDM

Drilling EDM can provide smaller and deeper holes than conventional drilling. This enables high precision diameter and roundness with excellent surface finish and burr-free.

Wire EDM

Wire EDM involves submerging a metal part in dielectric fluid, with an electrically charged wire fed through it. The electrical current passing through the wire generates sparks, effectively cutting the material to achieve the desired component shape. Wire EDM proves optimal when there’s adequate clearance above and below the part feature. Our wire diameters range from 0.05 to 0.25mm, with wire options including brass, zinc-coated, and diffusion-annealed variants. Wire cutting is categorized as fast, medium, or slow wire cutting based on accuracy, surface finish, and processing requirements.

Sinker EDM

Sinker EDM begins by machining an electrode into the desired cutout shape. This electrode is then charged and plunged into the metal component submerged in dielectric fluid. The resulting electrical discharge creates sparks, shaping the internal feature as intended. While Sinker EDM is versatile for crafting bevel gears, internal gears, spiral gears, and worm gears, it’s a slower and costlier process, making it suitable for select applications. Sinker EDM shines when creating hard-to-reach angular internal features like blind keyholes, impossible to machine using other methods.

Prototype and Parts Made Easy - Worldwide Delivery & Any Order Size

With many years of manufacturing experience, NPI offers the best solutions for all rapid prototyping and low to large volume manufacturing needs. We streamline the innovation cycle into four simple but effective steps.

01

Upload Your Design

02

Receive Design Analysis

03

Start Manufacruting

04

Receive Your Parts

How does Electrical Discharge Machining Work?

The wire follows a programmed path through the workpiece, eroding material in a controlled manner using electrical sparks. This innovative method produces a narrow kerf, allowing for exceptional detail and accuracy. Wire EDM is particularly beneficial for applications requiring small holes, fine edges, or challenging geometries.

Advantages of Wire EDM

- High Precision: Achieve tight tolerances and intricate designs with ease.

-Non-Contact Cutting: Eliminate distortion and damage often associated with traditional machining methods.

- Versatility: Suitable for a wide range of conductive materials, including hard metals and alloys.

- Ideal for Complex Parts:Perfect for delicate components requiring exceptional detail, such as molds, dies, and custom engineering parts.

Materials for wire EDM

At NPI, we specialize in wire EDM cutting for a wide range of conductive metals and alloys. Our capabilities include difficult-to-machine materials such as stainless steel, aluminum alloy, cobalt chrome, titanium, tungsten carbide, molybdenum, and Inconel. We can also produce parts from custom blends of different metals and alloys with superior accuracy.

- Tool steels

- Stainless steels

- Hardened steels

- High-speed steels

- Carbon steel

- High-speed cobalt

- Brass

- Bronze

- Copper

- Nickel

- Magnesium

- Molybdenum

- Carbide

- Titanium

- Inconel

- Hastelloy

- Tungsten

- Aluminum

Electrical Discharge Machining FAQs

There are three main types of EDM process.

Wire EDM: This method employs a thin wire as an electrode, capable of cutting intricate shapes and contours in conductive materials with high precision. It is ideal for producing complex parts with tight tolerances, often used in industries such as aerospace, medical, and electronics.

Sinker EDM (Ram EDM): This technique uses a custom-shaped electrode that is plunged into the workpiece to form detailed cavities and shapes. It is widely utilized for mold-making, die production, and manufacturing components with intricate geometries.

Hole-Drilling EDM: Specializes in drilling small, precise holes in hard materials. It is particularly useful for creating cooling holes in turbine blades and as a preliminary process for wire EDM.

Yes, Wire EDM can cut very thick materials with precision and efficiency. It is capable of cutting through materials up to 12 inches (300 mm) thick, depending on the machine and setup. The process uses a thin wire electrode to erode the material, allowing it to cut through dense and hard materials without distortion. This capability makes it ideal for applications requiring precise cuts in thick materials, such as large molds, heavy-duty machine components, and aerospace parts. The precision and versatility ensure consistent and accurate results, even in very thick materials.

Wire EDM machining services are a versatile and cost-effective process that can be used to create small-diameter parts with complex shapes and features. The technology is used in a variety of industries, from aerospace to medical devices.

Medical Machining

Power generation

Robotics

Cutting tools

Automotive

Additive manufacturing

Machine parts

Extrusion dies

Matched metal tooling

Progressive & fine blanking tooling

Interconnect Components

Fiber Optic Components

Aerospace Industry

Defense Industry

Looking for Online EDM Services?

- All uploads are secure and confidential.