CNC Turning Services Available Online

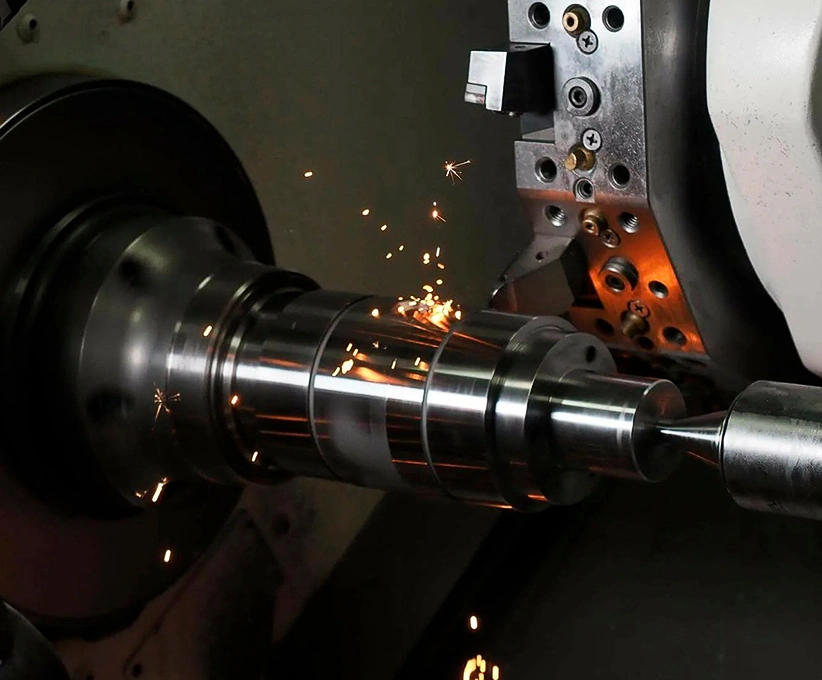

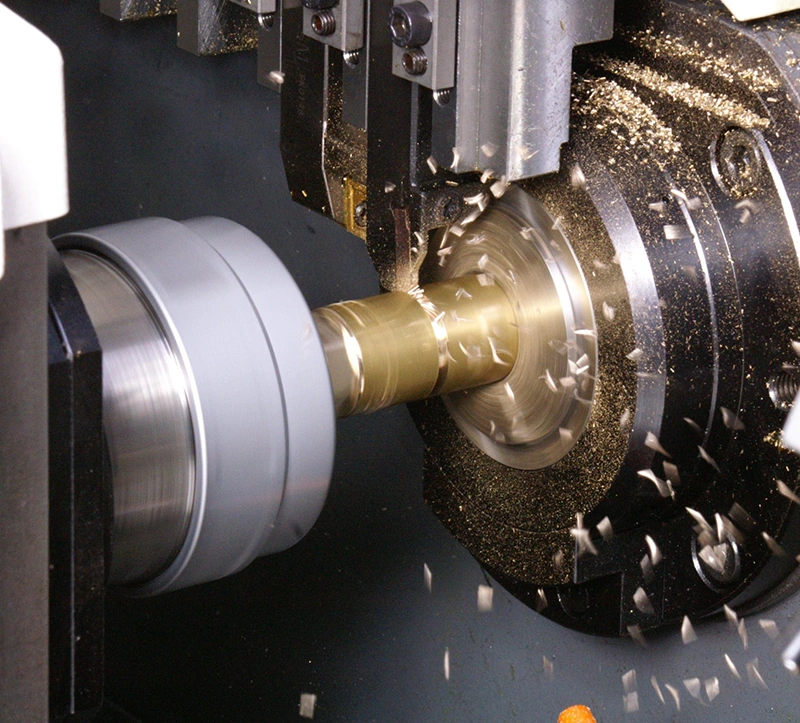

At NPI, we offer precision CNC Turning Services designed to deliver high-quality custom parts with quick turnaround times. Using advanced CNC turning equipment and skilled technicians, we can produce parts with tight tolerances and complex geometries.

- Ultra-tight tolerances of ± 0.005mm

- Prototype, low volume, high volume production

- 24/7 engineering support

- Industry Leading Security Standards

- Wide Range of Materials Options

- Cost-Effective Solutions

Enhancing Precision in CNC Turning

As a leading precision CNC turning parts manufacturer in China, we excel in essential processes, ensuring accuracy at every phase. Our advanced CNC turning services cater to a wide range of sizes, from 2mm to 100mm in diameter, offering comprehensive machining solutions such as milling, drilling, tapping, threading, boring, deburring, and facing. Utilizing state-of-the-art machinery, our experienced machinists and engineers collaborate with clients to design high-precision, custom turned parts tailored to specific requirements. With a commitment to quality, efficiency, and innovation, we deliver fast turnaround times, competitive pricing, and a variety of value-added services, including heat treatment, anodizing, and custom packaging. Trust us to provide unmatched precision and performance for diverse industries and applications. Contact us today to learn more about our CNC turning services!

CNC Turning Materials Selection

Metal Materials Series

| Image | Name | Description |

|---|---|---|

|

Steel | Offers high tensile strength and malleability. Used in construction, automotive, and manufacturing for structural components and tools. |

|

Stainless Steel | Known for corrosion resistance and durability. Employed in cutlery, medical equipment, and architectural applications. |

|

Titanium | Provides exceptional strength with low density. Utilized in aerospace, medical implants, and high-end sports gear. |

|

Brass | Combines strength and corrosion resistance. Commonly used in fittings, valves, and decorative items. |

|

Bronze | Features high corrosion resistance and strength. Suitable for sculptures, bearings, and marine hardware. |

|

Inconel | An austenitic family of superalloys with excellent heat and corrosion resistance. Used in gas turbines and chemical processing. |

|

Tool Steel | Designed for high hardness and wear resistance. Essential for the production of cutting tools and dies. |

|

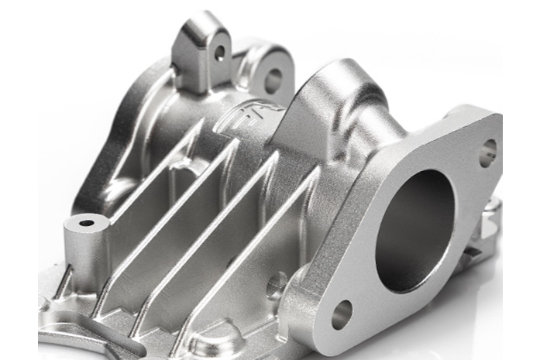

Aluminum Alloys | Lightweight with enhanced strength and corrosion resistance. Popular in aerospace, automotive, and consumer electronics. |

|

Maraging Steel | Known for its ultra-high strength and hardness. Used in precision instruments and high-stress mechanical parts. |

|

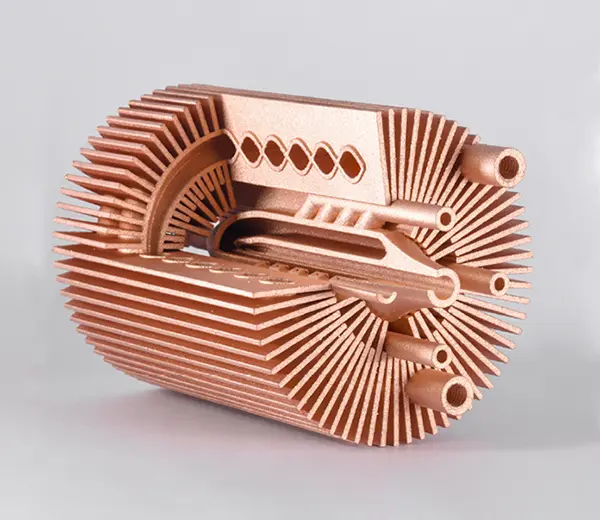

Copper Alloys | Exhibit high thermal and electrical conductivity. Widely used in electrical systems, heat exchangers, and coinage. |

Plastic Materials Series

| Image | Name | Description |

|---|---|---|

|

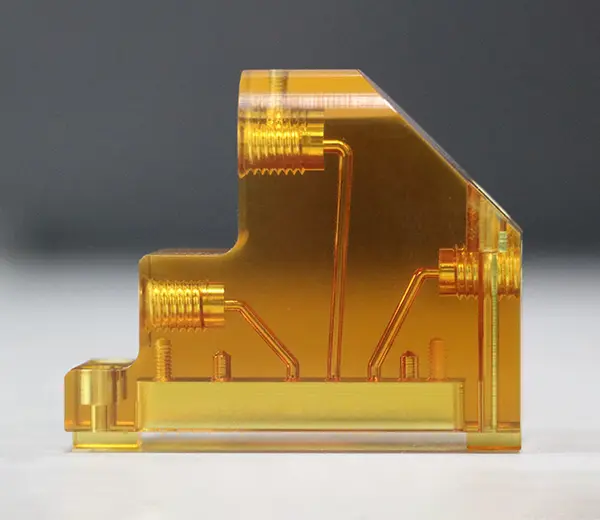

PC (Polycarbonate) | Known for its exceptional impact resistance and transparency. Used in eyewear, automotive parts, and durable plastic products. |

|

PA (Polyamide) | Strong, flexible, and resistant to chemicals. Common in fibers, automotive parts, and industrial components. |

|

ABS | Combines strength, rigidity, and toughness. Widely used in automotive and electronics. |

|

PVC (Polyvinyl Chloride) | Durable and cost-effective. Employed in plumbing, vinyl siding, and medical devices. |

|

Acrylic (PMMA) | Lightweight with high clarity. Ideal for aquariums, windows, and signage. |

|

Nylon | Resistant to wear, self-lubricating. Utilized in textiles, brushes, and mechanical parts. |

|

PSU (Polysulfone) | High-temperature resistance and rigidity. Suitable for electrical components and cookware. |

|

POM (Polyoxymethylene) | Stiff and resistant to abrasion. Common in gears, bearings, and automotive parts. |

|

PTFE (Teflon) | Non-stick and heat resistant. Used in non-stick cookware and industrial coatings. |

|

UHMWPE (ULtra-High Molecular Weight Polyethylene) | Exhibit high thermal and electrical conductivity. Widely used in electrical systems, heat exchangers, and coinage. |

- We can source any other material on request, but quotes take up to 48 hours.

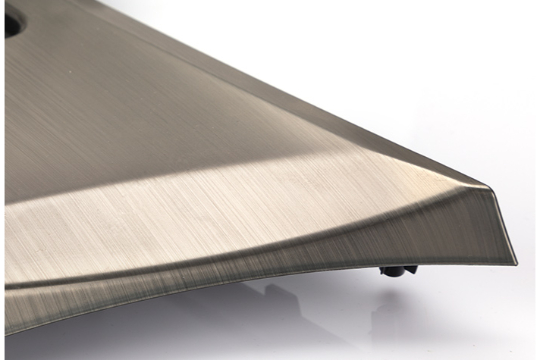

Surface Finishes for CNC Turning

CNC machining leaves visible tool marks during the process of removing portions of the block's surface to create desired shapes. If you don't want as-machined parts, select a surface finishing for your custom parts. At NOBLE, we offer several common surface finishes that help improve functionality and aesthetics.

| Name | Description | Materials | Color | Texture | |

|---|---|---|---|---|---|

|

Anodizing | Anodizing improves corrosion resistance, enhancing wear resistance and hardness, and protecting the metal surface. Widely used in mechanical parts, aircraft, and automobile parts, precision instruments, etc. | Aluminum | Clear, black, grey, red, blue, gold. | Smooth, matte finish |

|

Sand Blasting | Sand blasting results in parts with a smooth surface with a matte texture. Used mainly for visual applications and can be followed by other surface treatments. | ABS, Aluminum, Brass | N/A | Matte |

|

Powder Coating | Powder coating is a type of coating that is applied as a free-flowing, dry powder. Unlike conventional liquid paint which is delivered via an evaporating solvent, powder coating is typically applied electrostatically and then cured under heat or with ultraviolet light. | Aluminum, Stainless Steel, Steel | Black, any RAL code or Pantone number | Gloss or semi-gloss |

|

Electroplating | Electroplating can be functional, decorative or corrosion-related. Many industries use the process, including the automotive sector, in which chrome-plating of steel automobile parts is common. | Aluminum, steel, Stainless Steel | N/A | Smooth, Glossy finish |

|

Polishing | Polishing is the process of creating a smooth and shiny surface, either through physical rubbing of the part or by chemical interference. The process produces a surface with significant specular reflection, but in some materials is able to reduce diffuse reflection. | Aluminum, Brass, Stainless Steel, Steel | N/A | Glossy |

|

Brushing | Brushing is a surface treatment process in which abrasive belts are used to draw traces on the surface of a material, usually for aesthetic purposes. | ABS, Aluminum, Brass, Stainless Steel, Steel | N/A | Satin |

*Note: Table values are indicative. Actual specs can differ based on printer model, material, and settings. Delivery times depend on order volume and processing needs. Contact us for tailored recommendations on printing processes and parameters.

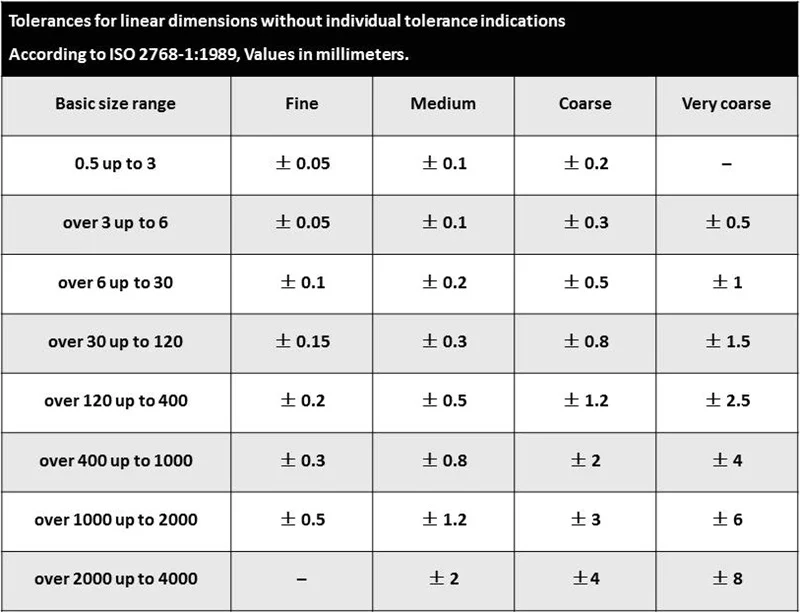

CNC Turning Tolerance

Fine (f)

Medium (m)

Distance Dimensions

For features of size (Length, width, height, diameter) and location (position, concentricity, symmetry) +/- 0.0005”.

Orientation and Form Dimensions

0-12″ +/- 0.005″, Angularity 1/2 degree. For 24″ and beyond please consult XMAKE’s Manufacturing Standards.

Edge Condition

Sharp edges will be broken and deburred by default. Critical edges that must be left sharp should be noted and specified on a print.

Lead Time

5 bussiness days for most projects.

*Note: The table serves as a guide. Outcomes vary by material, complexity, equipment, workload, and project specifics.

Advantages of Our CNC Turning Services

Prototype and Parts Made Easy - Worldwide Delivery & Any Order Size

With many years of manufacturing experience, NPI offers the best solutions for all rapid prototyping and low to large volume manufacturing needs. We streamline the innovation cycle into four simple but effective steps.

01

Upload Your Design

02

Receive Design Analysis

03

Start Manufacruting

04

Receive Your Parts

5 Steps for Producing CNC Turned Parts

- Prepare the G-Code

Convert your 3D CAD model into a G-code file using CAM software. This code provides the CNC lathe with precise machining instructions.

- Load the Material

Select a solid bar of plastic or metal and load it into the CNC lathe, ensuring it's securely clamped to avoid movement during machining.

- Secure the Workpiece

The chuck grips the workpiece as the spindle rotates, ensuring stability and precision throughout the process.

- Engage the Cutting Tool

Once the spindle reaches speed, a stationary cutting tool contacts the rotating workpiece, removing material according to the G-code until the desired shape is achieved.

- Finalize the Part

After machining, cut the finished part from the raw stock. Apply finishing processes like deburring or polishing to enhance appearance and durability before delivery.

By following these steps, we ensure an efficient CNC turning process that produces high-quality, precision-engineered parts. For more information about our CNC turning services, please contact us!

CNC Milling FAQs

Looking for Online CNC Turning Services?

- All uploads are secure and confidential.