Precision 5-Axis CNC Machining | Complex Parts, Expert Craftsmanship

Need intricate parts with tight tolerances? Our advanced 5-axis CNC machining services deliver high-precision, custom-made components with a tolerance as tight as 0.01mm, we can handle the most demanding projects. Get an Instant Quote Now! Experience the power of 5-axis CNC machining!

- Real-Time Production Updates

- Rapid Turnaround for Complex Parts

- Precision Feedback for Optimal 5-Axis Designs

- All uploads are secure and confidential.

- Enhanced Machining Flexibility

- High-Quality Surface Finishes

- Optimize Costs with Precision

NPI: Your Partner for 5-Axis CNC Excellence

As a leading global provider of 5-axis CNC machining services, NPI is committed to delivering exceptional quality and unparalleled service. Our state-of-the-art machinery and skilled engineers enable us to:

- Produce high-precision OEM parts

- Offer competitive pricing

- Ensure rapid turnaround times

Beyond 5-Axis Machining

In addition to our 5-axis capabilities, we provide a comprehensive range of machining solutions to meet your diverse needs. Whether you require simple or complex prototype parts, we have the expertise to deliver.

Ready to Experience the NPI Difference?

Contact us today to discuss your specific requirements and receive a customized quote. Let us help you take your manufacturing to the next level.

A Comprehensive Guide to Material Selection - 5-Axis CNC Machining

Metals

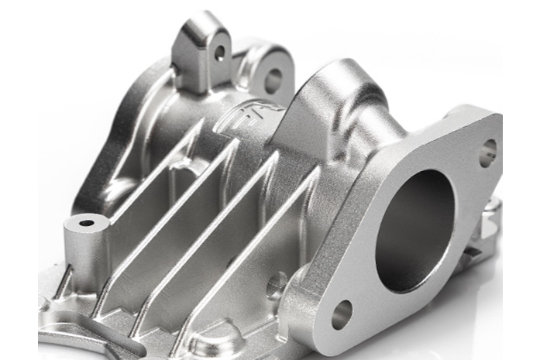

Aluminum

A lightweight, versatile, and easily machinable metal. It is widely used in aerospace, automotive, and consumer electronics industries.

Steel

A strong and durable metal, often used in structural components and tooling. Stainless steel is highly corrosion-resistant.

Titanium

A lightweight, high-strength metal with excellent corrosion resistance. It is commonly used in aerospace and medical applications.

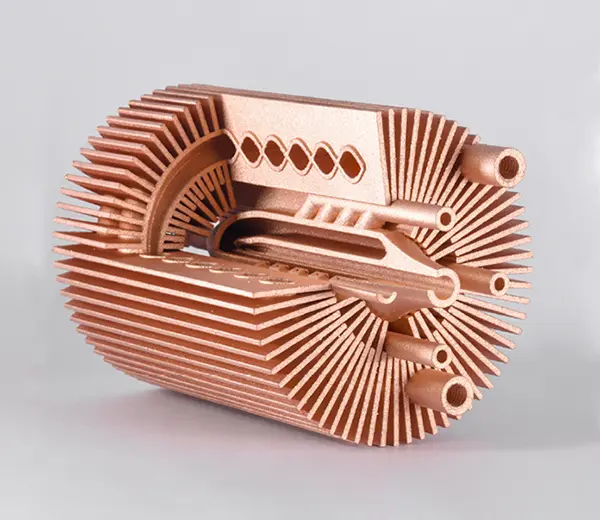

Copper

A highly conductive metal used in electrical and electronic components.

Brass

A copper alloy with good machinability and corrosion resistance. It is used in a variety of applications, including plumbing fixtures and musical instruments.

Plastics & Composite Materials

Acrylic

A transparent plastic with good machinability and impact resistance. It is used in signage, display cases, and lighting fixtures.

Delrin

A high-performance engineering plastic with excellent mechanical properties and chemical resistance. It is used in gears, bearings, and other precision components.

Nylon

A strong, durable plastic with good wear resistance and self-lubricating properties. It is used in a wide range of applications, including automotive and industrial components.

Polycarbonate

A tough, transparent plastic with high impact resistance. It is used in safety eyewear, bulletproof glass, and automotive components.

Carbon Fiber

A high-strength, lightweight composite material with excellent stiffness and thermal properties. It is used in aerospace, automotive, and sporting goods industries.

Fiberglass

oA versatile composite material with good strength-to-weight ratio and corrosion resistance. It is used in boat hulls, wind turbine blades, and other applications.

- We can source any other material on request, but quotes take up to 48 hours.

Factors Affecting Material Selection

By carefully considering these factors and selecting the appropriate material, manufacturers can optimize the 5-axis CNC machining process and produce high-quality, precision parts.

Part Geometry

Tolerances

Surface Finish

Cost

Material Selection for 5-Axis CNC Machining: A Closer Look

The choice of material significantly impacts the outcome of a 5-axis CNC machining process. Let's delve deeper into some of the key materials and their specific applications:

Metals

Advantages

Applications

Aluminum Alloys

Lightweight, excellent machinability, good corrosion resistance.

Aerospace components, automotive parts, electronics enclosures.

Titanium Alloys

High strength-to-weight ratio, excellent corrosion resistance, high-temperature tolerance.

Aerospace components, medical implants, high-performance machinery.

Stainless Steel

High strength, corrosion resistance, durability.

Medical instruments, food processing equipment, automotive parts.

Plastics

Advantages

Applications

Acrylic

Excellent clarity, good machinability, impact resistance.

Signage, display cases, prototypes.

Delrin

High strength, low friction, good chemical resistance.

Gears, bearings, electrical components.

PEEK

High temperature resistance, excellent mechanical properties, chemical resistance.

Aerospace components, medical devices, automotive parts.

Composite Materials

Advantages

Applications

Carbon Fiber

High strength-to-weight ratio, stiffness, and thermal stability.

Aerospace components, automotive parts, sporting goods.

Fiberglass

Corrosion resistance, good strength-to-weight ratio, versatility.

Boat hulls, wind turbine blades, automotive components.

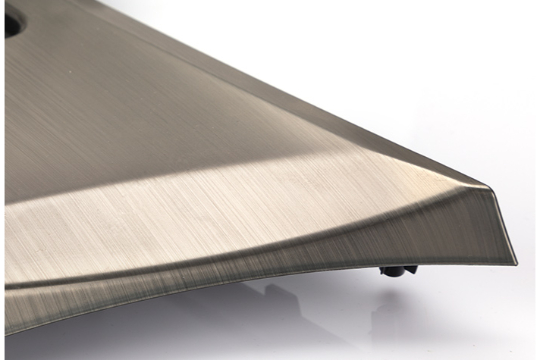

Surface Finishes for 5-Axis Machining

CNC machining leaves visible tool marks during the process of removing portions of the block's surface to create desired shapes. If you don't want as-machined parts, select a surface finishing for your custom parts. At NOBLE, we offer several common surface finishes that help improve functionality and aesthetics.

| Name | Description | Materials | Color | Texture | |

|---|---|---|---|---|---|

|

Anodizing | Anodizing improves corrosion resistance, enhancing wear resistance and hardness, and protecting the metal surface. Widely used in mechanical parts, aircraft, and automobile parts, precision instruments, etc. | Aluminum | Clear, black, grey, red, blue, gold. | Smooth, matte finish |

|

Sand Blasting | Sand blasting results in parts with a smooth surface with a matte texture. Used mainly for visual applications and can be followed by other surface treatments. | ABS, Aluminum, Brass | N/A | Matte |

|

Powder Coating | Powder coating is a type of coating that is applied as a free-flowing, dry powder. Unlike conventional liquid paint which is delivered via an evaporating solvent, powder coating is typically applied electrostatically and then cured under heat or with ultraviolet light. | Aluminum, Stainless Steel, Steel | Black, any RAL code or Pantone number | Gloss or semi-gloss |

|

Electroplating | Electroplating can be functional, decorative or corrosion-related. Many industries use the process, including the automotive sector, in which chrome-plating of steel automobile parts is common. | Aluminum, steel, Stainless Steel | N/A | Smooth, Glossy finish |

|

Polishing | Polishing is the process of creating a smooth and shiny surface, either through physical rubbing of the part or by chemical interference. The process produces a surface with significant specular reflection, but in some materials is able to reduce diffuse reflection. | Aluminum, Brass, Stainless Steel, Steel | N/A | Glossy |

|

Brushing | Brushing is a surface treatment process in which abrasive belts are used to draw traces on the surface of a material, usually for aesthetic purposes. | ABS, Aluminum, Brass, Stainless Steel, Steel | N/A | Satin |

*Note: Table values are indicative. Actual specs can differ based on printer model, material, and settings. Delivery times depend on order volume and processing needs. Contact us for tailored recommendations on printing processes and parameters.

5-Axis Machining Design Guidelines

Description

Applicable Materials

Minimum Feature Size

Features should be no smaller than 0.5 mm in width or depth to maintain structural integrity. Minimum available tool diameter SR0.6.

Linear Dimension

Achieve precision within +/-0.01 mm for linear dimensions to ensure consistent accuracy.

Hole Diameters (Not Reamed)

Machinable hole diameters range from 1 mm to 300 mm without reaming for precise sizing.

Shaft Diameters

Shaft diameters should be between 2 mm and 300 mm, considering tool access and torque needs.

Threads and Tapped Holes

Threads from M1 to M24 can be machined; provide adequate relief at the bottom of tapped holes.

Text

Minimum text height of 1.5 mm and depth of 0.1 mm for clear legibility after machining.

*Note: The table serves as a guide. Outcomes vary by material, complexity, equipment, workload, and project specifics.

Advantages of 5-Axis Machining at XMAKE

Prototype and Parts Made Easy - Worldwide Delivery & Any Order Size

With many years of manufacturing experience, NPI offers the best solutions for all rapid prototyping and low to large volume manufacturing needs. We streamline the innovation cycle into four simple but effective steps.

01

Upload Your Design

02

Receive Design Analysis

03

Start Manufacruting

04

Receive Your Parts

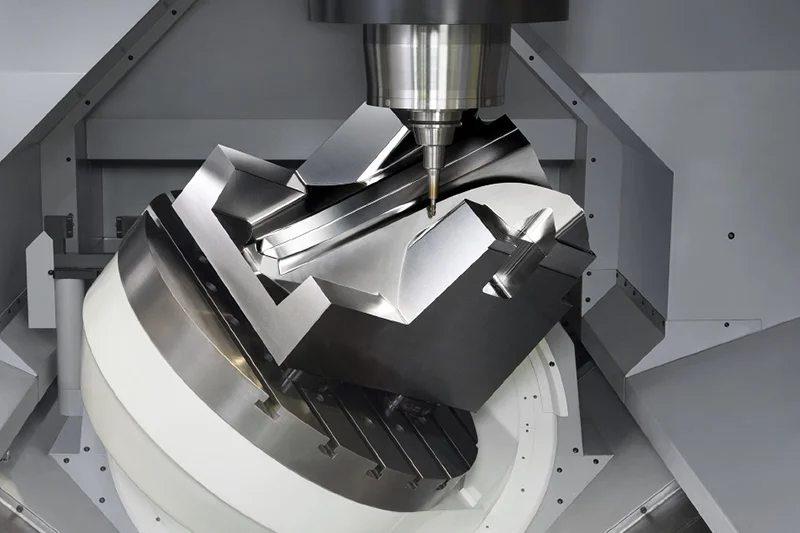

How does 5-Axis Machining Work?

5-axis machining uses simultaneous movement along five axes—three linear (X, Y, Z) and two rotational (A, B)—to precisely machine complex geometries and intricate details. This approach reduces setup time, enhances precision, and improves surface finish, making it ideal for high-tolerance and detailed components.

Simultaneous 5-Axis Machining vs 3+2 Axis CNC Machining

Simultaneous 5-Axis Machining

Simultaneous 5-Axis Machining involves the simultaneous movement of all five axes (three linear and two rotational) to cut intricate and complex geometries in a single setup, resulting in high precision and smooth surface finishes. This method is ideal for producing parts with intricate contours and complex shapes, as it allows for continuous toolpath adjustments and improved cutting dynamics.

3+2 Axis CNC Machining

3+2 Axis CNC Machining, on the other hand, uses three linear axes for cutting while the two rotational axes are fixed at specific angles during machining. This method offers excellent flexibility and precision for machining multiple sides of a part without repositioning, making it suitable for less complex geometries and batch production where simultaneous 5-axis movement is not required.

Why Choose NPI’s Custom 5-Axis Machining Services

Unmatched Precision

Choose XMAKE for 5-axis machining with tolerances of ±0.01mm, ensuring precise assembly and optimal performance.

Fast Turnaround

Rely on XMAKE’s advanced facilities for quick 5-axis machining production, keeping your projects on schedule and meeting crucial deadlines.

Expert Technical Support

Benefit from our specialists’ 5-axis machining expertise, offering personalized support for design optimization and superior component results.

5-Axis Machining FAQs

Looking for Online 5-Axis Machining Services?

- All uploads are secure and confidential.