Driving Automotive Innovation

NPI Prototype specializes in automotive prototype design and manufacturing, with expertise serving leading brands like BMW, Bentley, Lamborghini, and Land Rover.

- ISO 9001:2015 Certified

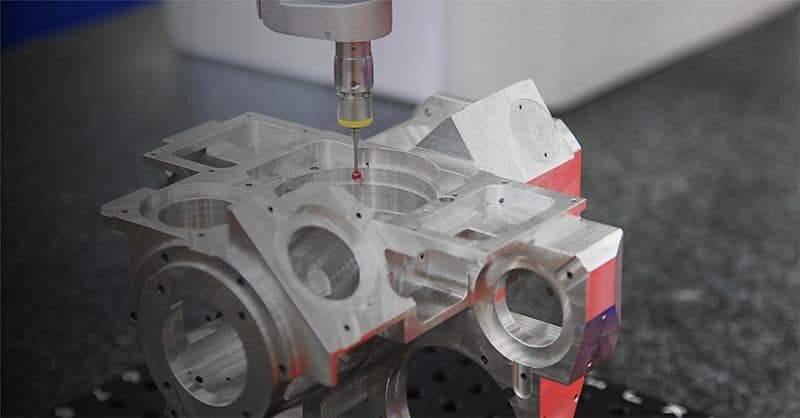

- Tolerances Up to ± 0.001mm

- 100% Quality Guaranteed

- Efficient Rapid Prototyping

- State-of-the-Art Technology Integration

- Tailored Innovative Solutions

Rapid Prototyping & Part Manufacturing for Automotive Industy

For over 10 years, NPI has delivered rapid prototyping, custom parts, and end-to-end production solutions to the automotive industry, ensuring quality and precision.

- Advanced Equipment & Cost-Effective Price

- Tight Tolerance of 0.001 mm

- 10+ years of Auto Parts Machining

- Free&Professional DFM Report

- 24/7 Engineering Support

Our Robust Automotive Parts Machining Capabilities

What materials are used in automotive prototyping?

In automotive prototyping, materials like metal, plastic, and silicone are commonly used, depending on the part and design needs. Stainless steel and aluminum alloys are most frequently chosen for their strength and durability, though magnesium, titanium, and copper alloys may also be used for specific requirements. Plastics like Acrylic, ABS, PC, and PPS, especially thermoplastics, are preferred for their flexibility and performance in automotive applications.

Metals

- Stainless steel

- Aluminum

- Titanium

- Copper

- Magnesium

- Bronze

- Carbon steel

- HT steel 4140

- Zamac

Plastics

- Acrylic

- ABS

- PC

- PPS

- PS

- Silicone rubber

- Urethane

- Epoxy

- PPS

- PS

Automobile Prototype Manufacturing

Automotive Lighting - Optics Prototype

- Acrylic CNC machining and transparent polishing

- Thin-walled transparent plastic (PC & PMMA) processing experience

- Excellent manual finishing and polishing techniques

- Advanced two-color multi-material (2K) molding process

Light Guides and Aluminum Mirrors

- Combining 5-axis precision milling with diamond machining technology

- More complex geometries and precise optical details can be achieved

- Minimum machining radius R0.1mm, surface tolerance ±0.02mm

- CNC milling roughness Ra(μm) 0.2 Mirror polishing Ra(μm) 0.05

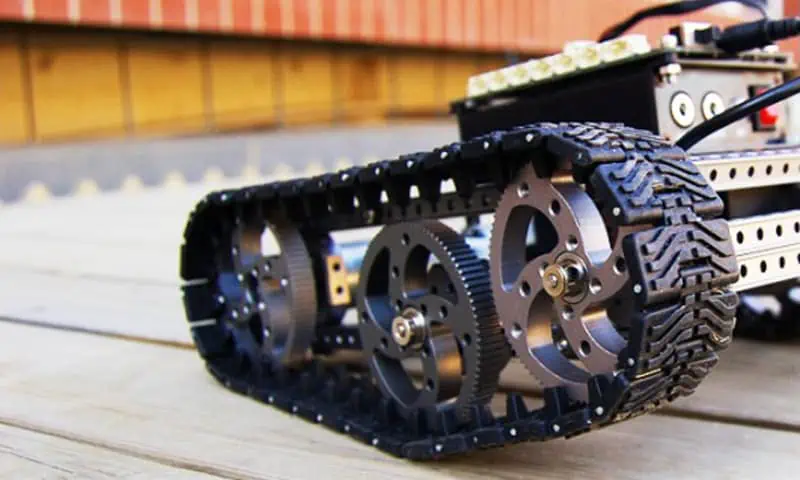

Automotive Mechanical Parts - Functional Prototypes

We specialize in functional prototyping of automotive mechanical components using CNC machining, 3D printing, vacuum casting, and rapid tooling. These advanced techniques provide real-world performance feedback, allowing for thorough testing and refinement of your car design to ensure optimal functionality and reliability in every stage of development.

- Simulate end-use mechanical functionality using the same materials as the final part.

- Create complication components to check form and fit.

- Create precision prototypes to check for design errors, dimensional differences.

Automotive FAQs

- Engine components such as cylinder blocks, cylinder heads, crankshafts, cajavascript:void(0);mshafts, and connecting rods.

- Transmission components such as gears, shafts, and housings.

- Suspension components such as control arms, knuckles, and spindles.

- Brake components such as rotors, calipers, and brackets.

- Steering components such as steering columns, racks, and pinions.

- Fuel system components such as fuel injectors, throttle bodies, and intake manifolds.

- Electrical components such as alternator housings and starter motor components.

Many parts of a car are best produced by machining, including engine components, transmission components, brake components, and suspension components, due to the precision and accuracy required for their function and performance.

Several technologies are prevalent in automotive rapid prototyping:

3D Printing (Additive Manufacturing): Techniques such as Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS) are widely used for creating prototypes from various materials.

CNC Machining: Computer Numerical Control machining allows for precise cutting and shaping of materials based on digital designs, suitable for metal and plastic parts.

Vacuum Casting: This method is often used for producing small batches of parts with high-quality surface finishes, typically using silicone molds.

Sheet Metal Fabrication : This method is a critical process in the automotive industry, involving the manipulation of flat sheets of metal into various shapes and components that are essential for vehicle construction. This process encompasses several techniques, including cutting, bending, and assembling, which allow manufacturers to create complex parts with precision and efficiency.

The choice of materials depends on the specific requirements of the prototype but commonly includes:

Plastics: Such as ABS, polycarbonate, and nylon for lightweight components.

Metals: Aluminum and stainless steel for parts requiring strength and durability.

Composites: Carbon fiber or fiberglass composites for high-performance applications.

While initial costs may seem high due to technology investment, rapid prototyping can lead to overall cost savings by reducing development time and minimizing errors during production. It allows manufacturers to identify issues early in the design phase, which can prevent costly changes later on.