CNC milling has a wide range of applications in the manufacturing industry, and its high precision, high efficiency and flexibility make it the preferred technology for machining various complex shape parts. The following is the specific application of CNC milling in the manufacturing industry:

1. Mold manufacturing

Application: CNC milling plays a key role in mold manufacturing and can accurately process complex shapes and structures of molds.

Advantages: Through CNC milling, the machining accuracy and surface quality of the mold can be improved, the mold manufacturing cycle can be shortened, and the production cost can be reduced.

2. Aerospace

Application: CNC milling is widely used in the aerospace field, for processing a variety of complex shape parts, such as engine blades, wheels and so on.

Advantages: It can meet the demand for high-precision, high-strength and lightweight parts in the aerospace field, and improve the performance and reliability of products.

3. Automobile manufacturing

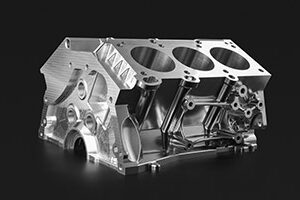

Application: CNC milling has a wide range of applications in the field of automotive manufacturing, such as engine cylinder block, crankshaft, camshaft and other key components processing.

Advantages: Through CNC milling, the processing accuracy and consistency of auto parts can be improved to ensure the performance and safety of the car.

4. Medical equipment

Applications: CNC milling also has important applications in medical equipment manufacturing, such as machining various precision medical devices and components.

Advantages: To ensure the accuracy and reliability of medical equipment, improve the performance and safety of medical equipment.

5. Electronics

Application: CNC milling is used in the manufacture of electronic products to process circuit boards, shells and other components.

Advantages: Through CNC milling, high-precision machining of electronic product components can be achieved to improve product performance and reliability.

6. Precision instruments

Application: CNC milling is used to process various precision parts and components in precision instrument manufacturing.

Advantages: It can meet the needs of precision instruments for high-precision and high-stability parts, and improve the performance and reliability of products.

7. General machinery manufacturing

Applications: CNC milling is used in general machinery manufacturing to process parts of various metal and non-metallic materials.

Advantages: Through CNC milling, the processing accuracy and surface quality of the parts can be improved, the production cost can be reduced, and the production efficiency can be improved.

Sum up

CNC milling has a wide range of application prospects in the manufacturing industry, and its high precision, high efficiency and flexibility make it the preferred technology for machining various complex shape parts. With the continuous development and technological progress of the manufacturing industry, CNC milling will play an important role in more fields, promoting the transformation and upgrading of the manufacturing industry and high-quality development.