SLA 3D Printing Service

- Live Project Tracking

- Get Parts in Days

- Quick Delivery of Intricate Designs

What is SLA 3D printing?

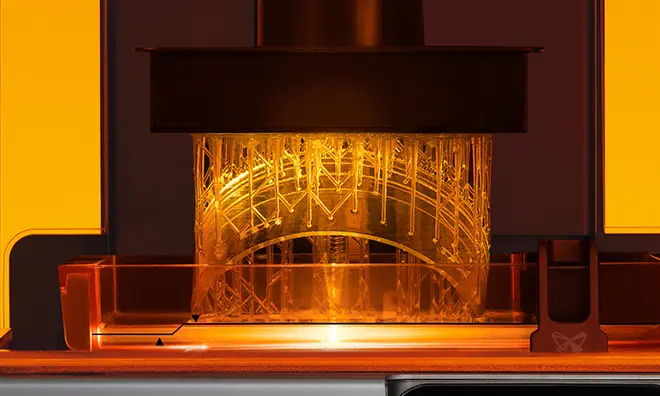

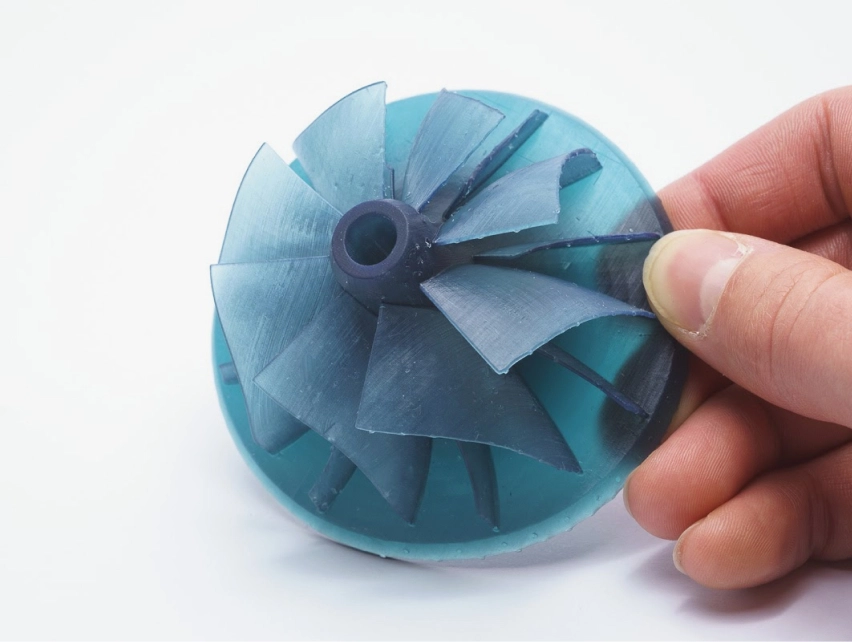

Stereolithography (SLA) is a 3D printing technology that utilizes ultraviolet (UV) light to cure liquid resin into solid objects layer by layer. Renowned for its ability to create highly detailed and smooth surfaces, SLA is ideal for producing intricate prototypes, complex designs, and end-use parts. This additive manufacturing method is widely used in various industries, including healthcare, automotive, and consumer goods, thanks to its precision and ability to capture fine details.

How does SLA 3D Printing Work?

Stereolithography (SLA) 3D printing operates through a series of precise steps:

- Design Creation: A 3D model is designed using CAD software.

- Slicing: The model is sliced into thin layers using slicing software.

- Preparation: The printer’s build platform is lowered into a vat of liquid resin.

- Laser Curing: A UV laser selectively cures the resin, layer by layer, following the sliced model’s outline.

- Layer Build-Up: The platform rises, and the process repeats until the model is fully formed.

- Post-Processing: The printed part is cleaned and cured to enhance durability.

SLA, MJF, SLS 3D Printing Materials

Our SLA and SLS Capability

We can make parts by SLA and SLS with different material. Pls see below our SLA and SLS capability.

If you have any other special material request by SLA/SLS, please check with our project manager.

| Material Type | Material Code | Process | Color |

Heat Deflection Temperature (HDT) |

Min Wallthickness |

Min Hole | Application | ABS Like | CUV9400E | SLA | White | 40-50 ℃ | 0.6mm | 1mm |

■ Automotive ■ Medical ■ Consumer electronics etc functional prototypes, water-resistant applications, appearance models with minimal finishing, durable concept models, high humidity environment applications and RTV patterns. |

|---|---|---|---|---|---|---|---|

| ABS/PBTLike | SOMOS14120 | SLA | Yellow | 40-50 ℃ | 0.6mm | 1mm |

■ Automotive ■ Medical ■ Consumer electronics etc functional prototypes, water-resistant applications, appearance models with minimal finishing, durable concept models, high humidity environment applications and RTV patterns. |

| ABS Like |

ABS LIKE watershed11122 |

SLA | Clear | 40-50 ℃ | 0.6mm | 1mm |

■ Automotive ■ Medical ■ Consumer electronics etc functional prototypes, water-resistant applications, appearance models with minimal finishing, durable concept models, high humidity environment applications and RTV patterns. |

| High tenacity ABS Like | ABS LIKE C-UV BESTY-1 | SLA | Yellow | 40-50 ℃ | 0.6mm | 1mm |

■ Automotive ■ Medical ■ Consumer electronics etc functional prototypes, water-resistant applications, appearance models with minimal finishing, durable concept models, high humidity environment applications and RTV patterns. |

|

Hight temperature resistant ABS like |

YG-H3001 | SLA | Grey | 80-100℃ | 0.6mm | 1mm |

■ Automotive ■ Medical ■ Consumer electronics etc functional prototypes, water-resistant applications, appearance models with minimal finishing, durable concept models, high humidity environment applications and RTV patterns. |

| Black Nylon | HP PA12 | SLS | Black | 95-150℃ | 0.5mm | 1.2mm |

■ Shell products; ■ automobile instrument panel and grid window; ■ assembly design; ■ functional prototype, etc |

| White Nylon | Precimid117XPro PA | SLS | White | 120-150℃ | 0.5mm | 1.2mm |

■ Shell products; ■ automobile instrument panel and grid window; ■ assembly design; ■ functional prototype, etc |

| Nylon GB | HP PA12GB | SLS | Black | 120-150℃ | 0.5mm | 1.2mm |

■Electric tool ■automobile industry ■machinery industry ■sports equipment ■ assembly design ■ functional prototype, etc |