On-Demand CNC Machining: Your Design, Our Precision

Need high-quality, custom-machined plastic and metal parts? Our on-demand CNC machining services deliver precision parts, from prototypes to full-scale production. Partner with our experts to bring your designs to life.

- Instant Pricing & DFM

- Parts as Fast as Few Days

- 95.4% of Parts Delivered On-time and To-spec

- Consistently Ensuring Precise Specifications

- Guaranteed Quick Delivery Times

- Comprehensive and Rigorous Checks

CNC Machining Capabilities at NPI

3-Axis CNC Milling

Experience precision and affordability with 3-axis CNC milling, perfect for simple, high-accuracy components.

4-Axis CNC Milling

Envision a design, and 4-axis milling can bring it to life. Multi-sided machining has never been easier.

5-Axis Machining

For intricate and detailed components, 5-axis milling is the superior solution. Bring your boldest designs to life.

CNC Milling Materials Selection

Metal Materials Series

-

Steel

-

Stainless Steel

-

Titanium

-

Brass

-

Bronze

-

Inconel

-

Tool Steel

-

Aluminum Alloys

-

Maraging Steel

-

Copper Alloys

Steel

Offers high tensile strength and malleability. Used in construction, automotive, and manufacturing for structural components and tools.

Stainless Steel

Known for corrosion resistance and durability. Employed in cutlery, medical equipment, and architectural applications.

Titanium

Provides exceptional strength with low density. Utilized in aerospace, medical implants, and high-end sports gear.

Brass

Combines strength and corrosion resistance. Commonly used in fittings, valves, and decorative items.

Inconel

An austenitic family of superalloys with excellent heat and corrosion resistance. Used in gas turbines and chemical processing.

Inconel

An austenitic family of superalloys with excellent heat and corrosion resistance. Used in gas turbines and chemical processing.

Tool Steel

Designed for high hardness and wear resistance. Essential for the production of cutting tools and dies.

Aluminum Alloys

Lightweight with enhanced strength and corrosion resistance. Popular in aerospace, automotive, and consumer electronics.

Maraging Steel

Known for its ultra-high strength and hardness. Used in precision instruments and high-stress mechanical parts.

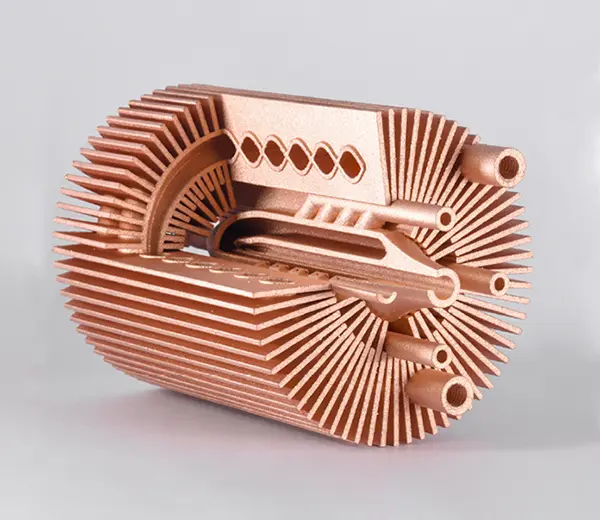

Copper Alloys

Exhibit high thermal and electrical conductivity. Widely used in electrical systems, heat exchangers, and coinage.

Plastic Materials Series

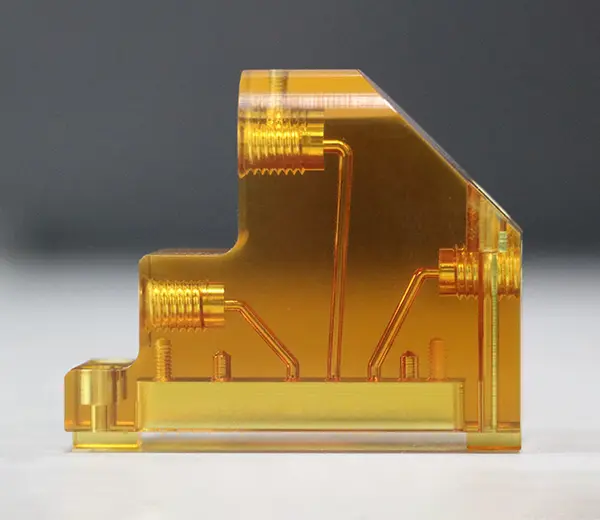

PC (Polycarbonate)

Known for its exceptional impact resistance and transparency. Used in eyewear, automotive parts, and durable plastic products.

PA (Polyamide)

Strong, flexible, and resistant to chemicals. Common in fibers, automotive parts, and industrial components.

ABS

Combines strength, rigidity, and toughness. Widely used in automotive and electronics.

PVC (Polyvinyl Chloride)

Durable and cost-effective. Employed in plumbing, vinyl siding, and medical devices.

Acrylic (PMMA)

Lightweight with high clarity. Ideal for aquariums, windows, and signage.

Nylon

Resistant to wear, self-lubricating. Utilized in textiles, brushes, and mechanical parts.

PSU (Polysulfone)

High-temperature resistance and rigidity. Suitable for electrical components and cookware.

POM (Polyoxymethylene)

Stiff and resistant to abrasion. Common in gears, bearings, and automotive parts.

PTFE (Teflon)

Non-stick and heat resistant. Used in non-stick cookware and industrial coatings.

- We can source any other material on request, but quotes take up to 48 hours.

CNC Milling Surface Finishes

Surface Treatment Method

Material Type

Colors

Surface Finish Precision (Ra)

Suitable Applications

Anodizing

Aluminum

Clear, Black, Grey,

Red, Blue, Gold

0.2 – 0.8 μm

Aviation, Electronics

Polishing

Stainless Steel

Gray

0.4 – 1.6 μm

Kitchenware, Medical

Sandblasting

Titanium Alloy

Dark Gray

1.6 – 3.2 μm

Sports Equipment

Plating

Copper

Red-Brown

0.8 – 1.6 μm

Decoration, Electrical

Chemical Plating

Magnesium Alloy

Light Gray

0.8 – 1.6 μm

Auto Parts

Powder Coating

Zinc Alloym

Silver

0.8 – 1.6 μm

Furniture Accessories

CNC Milling Tolerance

3-Axis

4-Axis

5-Axis

Maximum Part Size

4000x1500x600 mm

1000x500x500 mm

500x500x500mm

Minimum Part Size

1x1x5 mm

1x1x5 mm

1x1x5 mm

General Tolerances

±0.01 mm

±0.01 mm

±0.01 mm

Lead Time

Delivery of simple parts can be as fast as 1 day.

5 bussiness days for

most projects.

5 bussiness days for

most projects.

Edge Condition

Sharp corners will be removed in the form of a chamfer or radius. The size of the chamfer, or resulting radii, must be indicated on the drawing.

*Note: The table serves as a guide. For personalized advice on the ideal printing process and parameters to meet your specific requirements, please reach out to us.

Advantages of CNC Milling at NPI

Prototype and Parts Made Easy - Worldwide Delivery & Any Order Size

With many years of manufacturing experience, NPI offers the best solutions for all rapid prototyping and low to large volume manufacturing needs. We streamline the innovation cycle into four simple but effective steps.

01

Upload Your Design

02

Receive Design Analysis

03

Start Manufacruting

04

Receive Your Parts

How does CNC Milling Work?

CNC milling operates through a computer-controlled machine that precisely removes material from a solid workpiece to create custom shapes and designs. The process begins with a digital design, typically created using Computer-Aided Design (CAD) software. This design is then converted into a toolpath via Computer-Aided Manufacturing (CAM) software, which directs the CNC machine on how to move the cutting tool. The milling machine employs various tools, such as end mills and drills, to execute the design with high precision. Throughout the operation, the machine's movements are carefully synchronized, allowing for intricate detailing and smooth finishes on a range of materials.

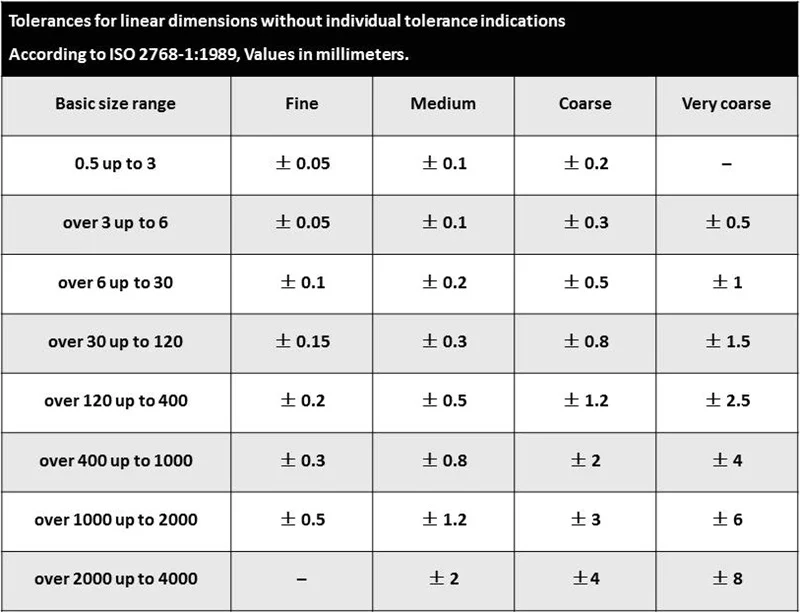

CNC Machining Tolerances

At NPI, our standard tolerances adhere to ISO 2768 specifications, applying ISO 2768 medium tolerances for machined plastics and ISO 2768 fine tolerances for machined metals. We can typically achieve CNC machining tolerances ranging from ±0.005″ (±0.125mm) to ±0.002″ (±0.05mm). For projects requiring tighter tolerances, we request a detailed 2D drawing containing all necessary information. Our experienced engineering team will communicate with you regarding critical dimensional tolerances, ensuring we deliver the highest level of precision for your CNC machining needs. Trust NPI for superior quality and precision in all your machining projects.

CNC Milling FAQs

Looking for Online CNC Milling Services?

- All uploads are secure and confidential.