Mass Production Simplified

Elevate your production potential with NPI's vast manufacturing network. Enjoy flexible order volumes, diverse processes, and expert engineering for seamless prototyping and custom parts, ensuring high-quality results at competitive prices. Discover the advantage today!

- Parts Machined in 1 Day

- Cost-Effective Parts in just a few days

- Save over 20% on Quality Parts

- All uploads are secure and confidential.

- Delivery Nationwide as Fast as 24 Hours

- Low-Volume Manufacturing

- Superior Quality Assurance

Our Complete Custom Manufacturing Services

At NPI, we excel in high-quality prototypes and precision parts tailored to various industries. Utilizing our rapid prototyping expertise, we turn your ideas into market-ready products quickly. Enhance your project timelines and product development by contacting us today for innovative manufacturing solutions!

Rapid Prototyping

We provide high-quality rapid prototypingservices to support your new product development goals.

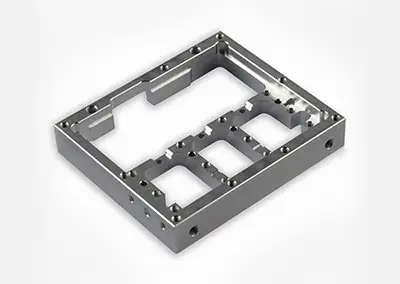

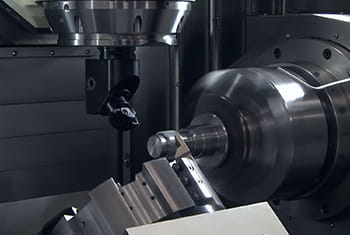

CNC Machining

By using CNC milling & turning, we canmake a wide range of prototypes and production parts.

Injection Molding

Not only can plastic prototypes be produced, but also parts can be mass-produced at competitive prices.

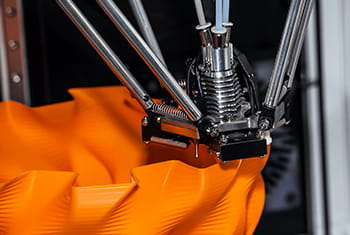

3D Printing

Versatile enough to quickly create complex geometries in a variety of materials, perfect for innovative designs.

Sheet Metal Fabrication

Versatile manufacturing process for a wide range of metal parts to support unique applications.

Vacuum Casting

Provides a reliable alternative to injection molding for needs for clear, color-matched or specialty finished parts.

We Ensure Quality in Every Step

Pre-Production

Technical assessment

Prior to production, our engineering team conducts a thorough technical assessment of your design, evaluating key factors like materials, surface finish, structure, and processing details in your 2D and 3D drawings to ensure optimal results.

Material verification

Upon request, we will provide certification for materials or material datasheet used for making your components. This report sources from the raw material manufacturer and generally includes critical details such as heat number, material grade, dimensions, mechanical properties, and chemical analysis for transparency and quality assurance.

In-Production

On-site inspection system

In precision machining, maintaining accurate material positioning is crucial. An on-site inspection system automates position checks and adjustments, preventing potential issues early in the process. This proactive approach not only enhances efficiency but also saves both time and costs in production. Optimizing machining precision has never been easier.

In-process quality control

At NPI, we strictly follow ISO 9001:2015 standards. The quality control staffs performs routine inspections on all produced parts every two hours to minimize risks and ensure exceptional quality.

generally includes critical details such as heat number, material grade, dimensions, mechanical properties, and chemical analysis for transparency and quality assurance.

Final-Production

Full-dimensional inspection report

For all orders, we provide full dimensional inspection reports on request. This report will include detailed metrics such as part quantity, critical dimensions, threads, tolerances, thicknesses, depths, and overall part appearance to ensure quality and compliance.

Packaging + Shipping

Ensuring that the parts we manufacture are of the highest quality is important. To minimize risks during shipping, we implement a robust four-layer packaging system: 1. wrapping paper, 2. EPE, 3. foam, and 4. a sturdy paper or wooden box. This meticulous approach ensures the delivery of high-quality and aesthetically pleasing parts, safeguarding them every step of the way.

Prototype and Parts Made Easy - Worldwide Delivery & Any Order Size

With many years of manufacturing experience, NPI offers the best solutions for all rapid prototyping and low to large volume manufacturing needs. We streamline the innovation cycle into four simple but effective steps.

01

Upload Your Design

02

Receive Design Analysis

03

Start Manufacruting

04

Receive Your Parts

Precision Massive Production for Diverse Industries

Mass Production FAQs

Looking for Online Mass Production Services?

- All uploads are secure and confidential.