Custom Online CNC Machining Service

Experience precision CNC machining with our on-demand services. Get top-quality Screw, Aluminum, and Stainless Steel machining, plus rapid prototyping—all delivered in days or less.

- Parts Machined in 1 Day

- 0.01mm Tolerances

- Instant CNC Quotes, Comprehensive DFM

- Delivery Nationwide as Fast as 24 Hours

- Low-Volume Manufacturing

- Superior Quality Assurance

CNC Machining Capabilities at NPI

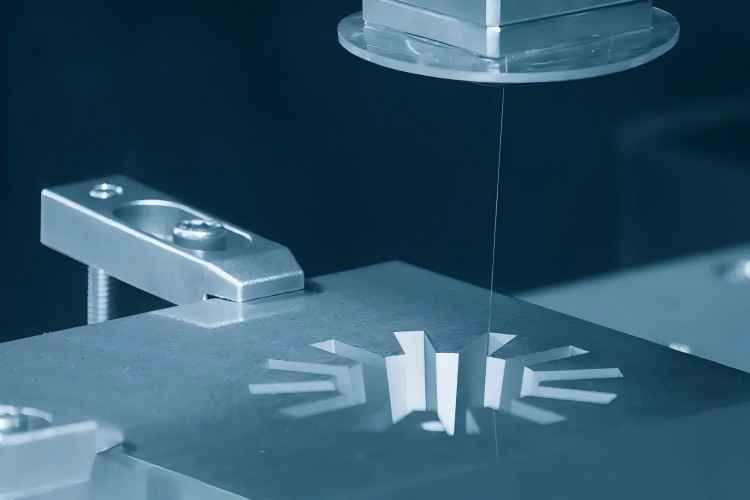

Electrical Discharge Machining (EDM)

Crafts metal with electrical sparks, suited for complex or hardened materials.

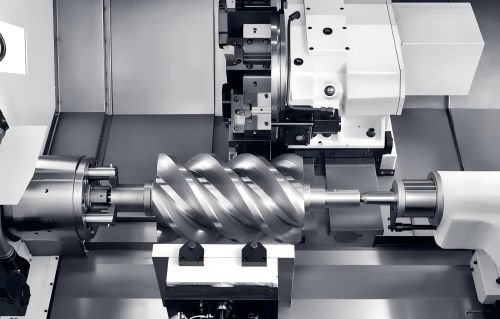

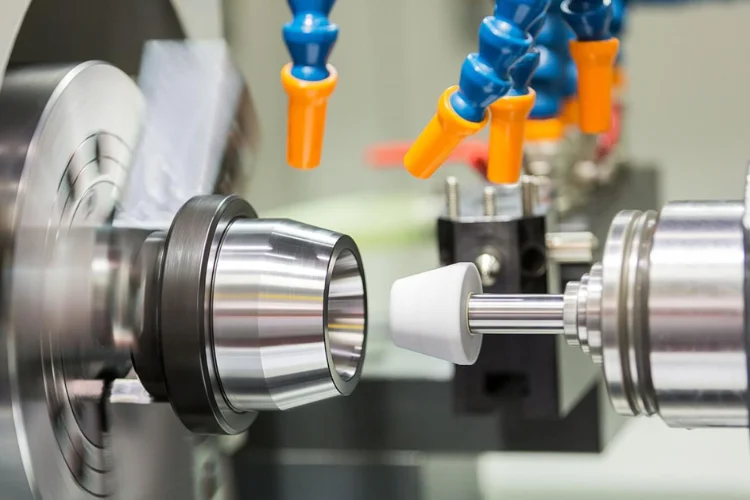

CNC Milling

3-5 axis capability for crafting a wide range of parts in aerospace, and medical industries.

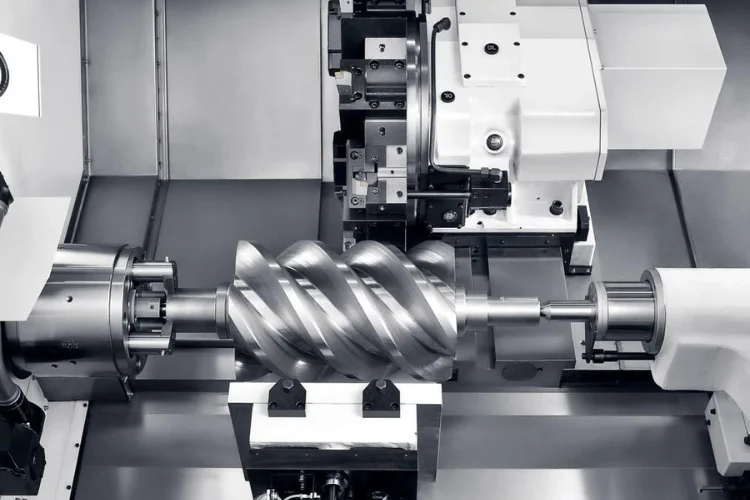

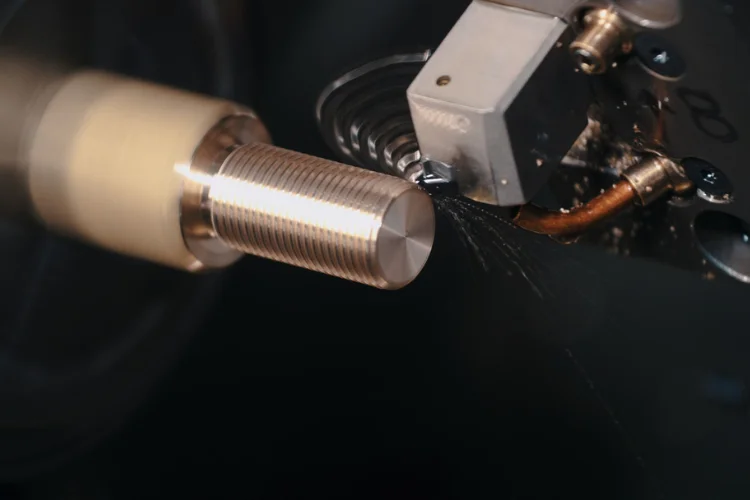

CNC Turning

Generates cylindrical forms, from straight forward holes to elaborate profiles.

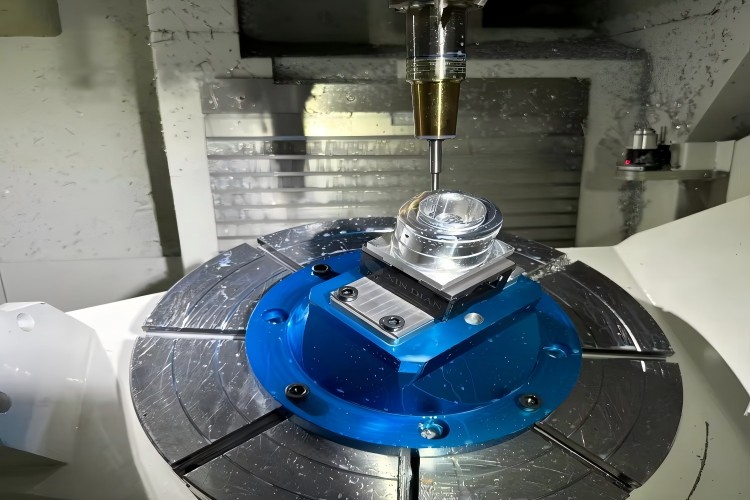

5-Axis Machining

Enables intricate shapes through comprehensive tool and workpiece movement.

CNC Milling Materials Selection

Metal Materials Series

| Image | Name | Description |

|---|---|---|

|

Steel | Offers high tensile strength and malleability. Used in construction, automotive, and manufacturing for structural components and tools. |

|

Stainless Steel | Known for corrosion resistance and durability. Employed in cutlery, medical equipment, and architectural applications. |

|

Titanium | Provides exceptional strength with low density. Utilized in aerospace, medical implants, and high-end sports gear. |

|

Brass | Combines strength and corrosion resistance. Commonly used in fittings, valves, and decorative items. |

|

Bronze | Features high corrosion resistance and strength. Suitable for sculptures, bearings, and marine hardware. |

|

Inconel | An austenitic family of superalloys with excellent heat and corrosion resistance. Used in gas turbines and chemical processing. |

|

Tool Steel | Designed for high hardness and wear resistance. Essential for the production of cutting tools and dies. |

|

Aluminum Alloys | Lightweight with enhanced strength and corrosion resistance. Popular in aerospace, automotive, and consumer electronics. |

|

Maraging Steel | Known for its ultra-high strength and hardness. Used in precision instruments and high-stress mechanical parts. |

|

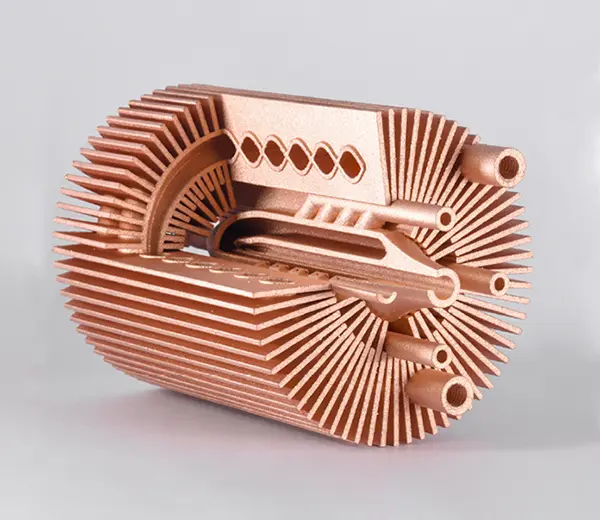

Copper Alloys | Exhibit high thermal and electrical conductivity. Widely used in electrical systems, heat exchangers, and coinage. |

Plastic Materials Series

| Image | Name | Description |

|---|---|---|

|

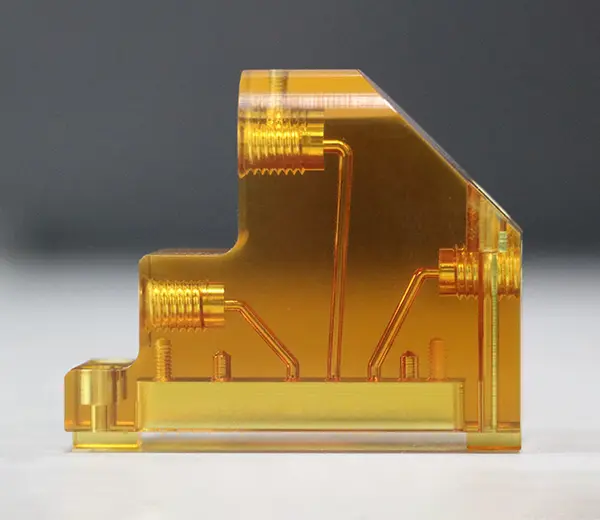

PC (Polycarbonate) | Known for its exceptional impact resistance and transparency. Used in eyewear, automotive parts, and durable plastic products. |

|

PA (Polyamide) | Strong, flexible, and resistant to chemicals. Common in fibers, automotive parts, and industrial components. |

|

ABS | Combines strength, rigidity, and toughness. Widely used in automotive and electronics. |

|

PVC (Polyvinyl Chloride) | Durable and cost-effective. Employed in plumbing, vinyl siding, and medical devices. |

|

Acrylic (PMMA) | Lightweight with high clarity. Ideal for aquariums, windows, and signage. |

|

Nylon | Resistant to wear, self-lubricating. Utilized in textiles, brushes, and mechanical parts. |

|

PSU (Polysulfone) | High-temperature resistance and rigidity. Suitable for electrical components and cookware. |

|

POM (Polyoxymethylene) | Stiff and resistant to abrasion. Common in gears, bearings, and automotive parts. |

|

PTFE (Teflon) | Non-stick and heat resistant. Used in non-stick cookware and industrial coatings. |

|

UHMWPE (ULtra-High Molecular Weight Polyethylene) | Exhibit high thermal and electrical conductivity. Widely used in electrical systems, heat exchangers, and coinage. |

- We can source any other material on request, but quotes take up to 48 hours.

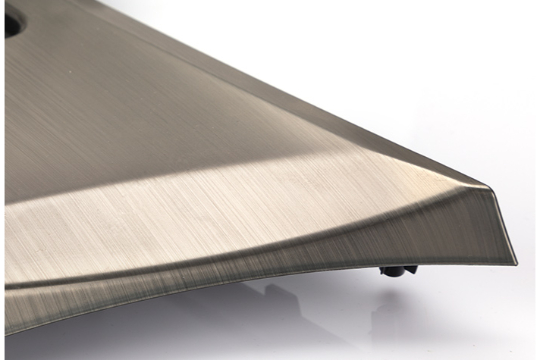

Surface Finishes for CNC Machining

CNC machining leaves visible tool marks during the process of removing portions of the block's surface to create desired shapes. If you don't want as-machined parts, select a surface finishing for your custom parts. At NPI, we offer several common surface finishes that help improve functionality and aesthetics.

| Name | Description | Materials | Color | Texture | |

|---|---|---|---|---|---|

|

Anodizing | Anodizing improves corrosion resistance, enhancing wear resistance and hardness, and protecting the metal surface. Widely used in mechanical parts, aircraft, and automobile parts, precision instruments, etc. | Aluminum | Clear, black, grey, red, blue, gold. | Smooth, matte finish |

|

Sand Blasting | Sand blasting results in parts with a smooth surface with a matte texture. Used mainly for visual applications and can be followed by other surface treatments. | ABS, Aluminum, Brass | N/A | Matte |

|

Powder Coating | Powder coating is a type of coating that is applied as a free-flowing, dry powder. Unlike conventional liquid paint which is delivered via an evaporating solvent, powder coating is typically applied electrostatically and then cured under heat or with ultraviolet light. | Aluminum, Stainless Steel, Steel | Black, any RAL code or Pantone number | Gloss or semi-gloss |

|

Electroplating | Electroplating can be functional, decorative or corrosion-related. Many industries use the process, including the automotive sector, in which chrome-plating of steel automobile parts is common. | Aluminum, steel, Stainless Steel | N/A | Smooth, Glossy finish |

|

Polishing | Polishing is the process of creating a smooth and shiny surface, either through physical rubbing of the part or by chemical interference. The process produces a surface with significant specular reflection, but in some materials is able to reduce diffuse reflection. | Aluminum, Brass, Stainless Steel, Steel | N/A | Glossy |

|

Brushing | Brushing is a surface treatment process in which abrasive belts are used to draw traces on the surface of a material, usually for aesthetic purposes. | ABS, Aluminum, Brass, Stainless Steel, Steel | N/A | Satin |

*Note: Table values are indicative. Actual specs can differ based on printer model, material, and settings. Delivery times depend on order volume and processing needs. Contact us for tailored recommendations on printing processes and parameters.

CNC Machining Tolerance

Fine (f)

Medium (m)

Coarse (c)

Very Coarse (v)

Linear Size (0.5~3mm)

±0.01 mm

±0.02 mm

±0.05 mm

±0.01 mm

Radius of Fillet (0.5~3mm)

±0.01 mm

±0.02 mm

±0.05 mm

±0.01 mm

Chamfer Height (0.5~3mm)

±0.02 mm

±0.02 mm

±0.05 mm

±0.02 mm

Angular Size ≤10°

±0.5°

±0.05 mm

±0.01 mm

±0.02 mm

Edge Condition

Sharp corners will be removed in the form of a chamfer or radius. The size of the chamfer, or resulting radii, must be indicated on the drawing.

*Note: The table serves as a guide. For personalized advice on the ideal printing process and parameters to meet your specific requirements, please reach out to us.

Prototype and Parts Made Easy - Worldwide Delivery & Any Order Size

With many years of manufacturing experience, NPI offers the best solutions for all rapid prototyping and low to large volume manufacturing needs. We streamline the innovation cycle into four simple but effective steps.

01

Upload Your Design

02

Receive Design Analysis

03

Start Manufacruting

04

Receive Your Parts

Our Top Demanded CNC Machining Solution

We offer a range of CNC machining services tailored to your needs. From high-precision milling to laser cutting, we provide scalable, efficient, and high-quality manufacturing solutions for any industry.

-

CNC Milling

-

CNC Turning

-

CNC Grinding

-

CNC Drilling

-

CNC Routing

-

Swiss & Screw Machining

-

Small Batch CNC Machining

-

Sheet Metal Fabrication

-

Metal Casting Service

-

Wire EDM Machining

-

Laser Cutting Services

-

Custom Jig and Fixture

CNC Milling

Our CNC milling services offer top-notch precision for your parts. We use advanced multi-axis machines to craft detailed designs and complex shapes. These can be made from materials like aluminum, steel, and plastics.

This service works well for everything, from prototypes to large production runs. It delivers perfect accuracy and a fast turnaround.

CNC milling reduces waste and maintains tight tolerances. You can always expect high-quality results with every order.

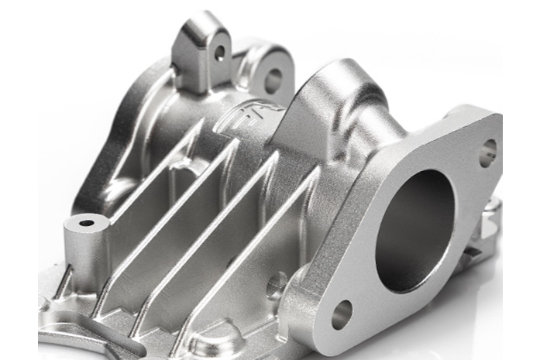

CNC Turning

CNC turning is great for making cylindrical parts. It works well for items like shafts, hubs, and bushings. Our high-speed turning process ensures smooth surfaces and accurate dimensions.

We use automated, high-precision lathes to work with both metals and plastics. This means we can deliver consistent results quickly.

Whether you’re ordering a small batch or a large one, CNC turning keeps everything accurate and helps save time and costs.

CNC Grinding

CNC grinding is the way to go when you need parts with a smooth finish and exact precision. We offer surface, cylindrical, and internal grinding and it removes material with incredible accuracy.

Grinding is especially useful for parts that need a polished finish or tight tolerances, and it works perfectly with tougher materials.

You’ll often find, CNC grinding used in aerospace, automotive, and medical industries because it delivers top-quality results for high-performance components.

CNC Drilling

Our CNC drilling service is fast and accurate. We use special tools to drill holes to the exact size and depth. This makes sure all parts are consistent.

Our machines can work with different materials and sizes which makes it great for small or large orders.

CNC Routing

Our CNC routing service is ideal for cutting non-metal materials. They are like wood, plastic, and composites.

We use computer-guided routers to make detailed designs with minimal waste.

It’s perfect for industries that need fast, high-volume, precise cuts. Every cut is exact and repeatable.

Swiss & Screw Machining

Swiss and screw machining is ideal for making small, intricate parts. We use automated lathes to create parts with tight tolerances.

This service works well for industries like medical, electronics, and aerospace.

It’s perfect for high-volume production of small-diameter components. It also handles both simple and complex designs efficiently.

Small Batch CNC Machining

If you need prototypes or small production runs, our small-batch CNC machining service is a great option. We offer flexibility and cost savings. You can get custom parts without large order commitments.

This service provides fast delivery and lower costs. It’s ideal for startups or projects which only need a small number of parts.

Sheet Metal Fabrication

Our sheet metal fabrication service combines precision with efficiency. We use advanced CNC technology to cut, bend, and shape sheet metal into almost any form.It supports industries like automotive and consumer products.With fast turnarounds, our sheet metal service offers durable and cost-effective solutions.

Material: Mild steel, SPCC, Q235, Stainless steel 201, 304, 316, Aluminum Alloy 5052,6061, Galvanized steel, SECC, SGCC etc.

Process: Laser cutting, CNC Punching, Stamping, CNC Bending, Riveting, Welding etc.

Surface finish : Powder coating, zinc plating, anodized,polishing and brushed

Application : electronic enclosures, industry & commercial usage etc.

Metal Casting Service

Die casting is a high pressure metal casting process that forces molten metal into a mold. It produces dimensionally accurate precision metal parts that have a flawless smooth finish. Its ability to produce detailed parts makes it perfect for the mass production of products. Die castings are typically created from non-ferrous metals like zinc, copper, aluminum, magnesium, lead, pewter, and tin.

NPI’s metal casting service helps you create strong, complex parts. We use advanced methods to cast durable parts at a lower cost, especially for large production runs.Whether you need detailed castings or simple ones, we ensure each part has tight tolerances and high-quality materials.

This service works well for industrial and structural needs.

Wire EDM Machining

Wire EDM, or wire electrical discharge machining, is a machining process that utilizes a fine, electrically charged wire to cut conductive materials with extreme precision. It gives precise cuts for tough materials. Our machines use a thin wire to wear down the material. This allows for fine cuts without losing the strength of the material.

This process is great for making complex shapes with tight tolerances. We often use Wire EDM with metals like stainless steel, titanium, and hardened tool steel.

Aerospace, medical, and electronics industries depend on it to make precise parts.

Laser Cutting Services

Our laser cutting service provides fast, accurate cuts for metals and other materials. We use high-powered lasers for smooth, precise cuts.

Laser cutting is great for simple or complex designs. It gives sharp edges with little waste and makes it ideal for industries needing quick, high-quality results.

Custom Jig and Fixture

Our custom jig and fixture services help improve the accuracy of your production process. We design them based on your specific needs, ensuring perfect alignment and repeatability for every product.

If you have existing design files for jigs or fixtures, we can machine them precisely according to your specifications, guaranteeing consistency and reliability in output.

From complex assemblies to simple tasks, our jigs and fixtures streamline your workflow, reducing setup times and minimizing errors.

By optimizing your production process, we enable you to achieve higher quality results and increased throughput, ultimately enhancing your operational efficiency and competitiveness in the market.

Precision CNC Machining for Diverse Industries

Why Choose NPI’s Custom CNC Machining Service

High Precision

Choose NPI for CNC machining accuracy within ±0.005mm, ensuring your parts meet the tightest tolerances.

The Perfect Finish

Elevate your CNC Machined parts with high-quality finishing processes, including anodizing, polishing, plating, powder coating, and more.

Fast Turnaround Times

Experience industry-leading turnaround with NPI, delivering 95% of projects up to 30% faster than the competition.

Cost-Efficiency

Save up to 20% on production costs with NPI's optimized CNC machining processes and bulk order discounts.

Wide Material Compatibility

Utilize NPI's CNC services for a broad range of materials, including aluminum, stainless steel, and plastics, with over 50 different materials supported.

Quality Certifications

Rest assured with NPI's ISO 9001 certification, reflecting our commitment to quality and environmental responsibility.

NPI Customer Success: Solving Challenges Together

I have recently been in business with NPI and was thoroughly impressed by their impeccable service. Their dedicated staff helped us with all our needs and made sure we met our deadlines. Do take a look at they have to offer, they are a very reliable company to be in business with!

Alexa A.

Product Designer

Over the last year I have worked with Yuna at NPI . I have placed nearly a dozen orders for a total of about 70 unique custom parts for medical product prototypes (plastics, metals, lathe, mill, EDM, heat treatment, laser marking). Most of which have been very complex multi-axis / multi setup parts, and many with tight tolerances needs. I have continually been impressed with the part quality, the pricing, and Yuna ‘s customer service. I think I have always had quotes within a day, and usually have parts in my hands in less than 3 weeks.

All that said, please don't use them, because I want them to keep making parts for me and don't want you bogging them down with your parts, haha 😉

Nick S.

R&D Director

As a Mechanical Engineer it's always a pleasure to receive parts that look exactly like my CAD design. Great quality and precision on the parts, finishing option such as sand blasting, anodizing and silk printing are great (and all that for really good pricing). Good communication throughout the orders which make things really easy! NPI is really professional, parts are well packed for shipping. Definitely recommend!

Garret K.

Vice President

CNC Machining FAQs

Looking for Online CNC Machining Services?

- All uploads are secure and confidential.