Custom Precision 3D

Printing Service

Our custom 3D printing services cater to your specific requirements, offering rapid prototypes and full-scale production parts with unmatched speed and precision.

- As fast as 1 day

- Competitive Price

- Qualified system

- All uploads are in confidential

- 24-Hour Rapid Parts Delivery

- Competitive 3D Printing Prices

- Uncompromising Quality Assurance

3D Printing Service at NPI

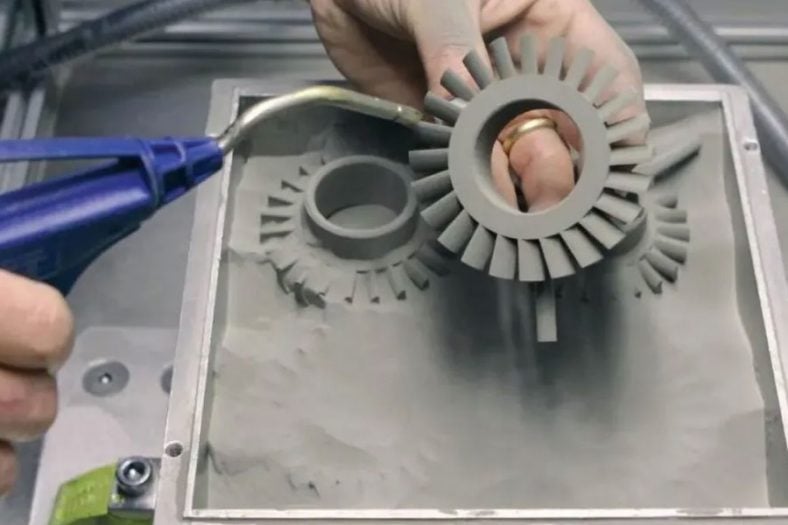

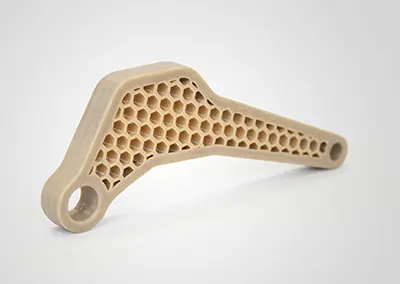

SLS

SLS fuses powdered material layer by layer using a laser, producing robust and durable parts. It’s excellent for complex geometries and end-use applications.

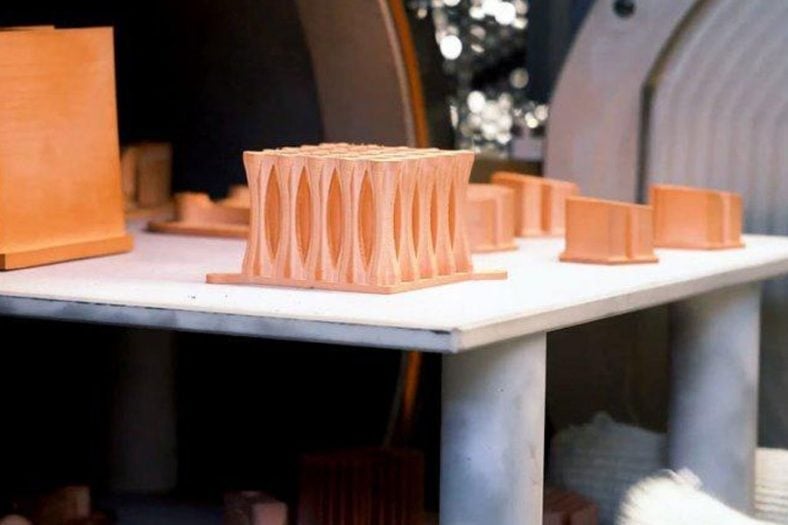

MJF

HP MJF employs a fusing agent and heat to produce durable, functional parts with intricate details and outstanding mechanical properties.

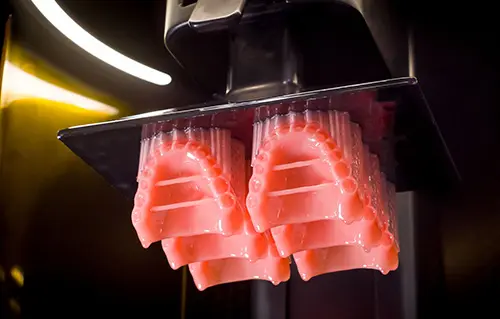

SLA

SLA utilizes a laser to cure liquid resin into solid parts with high precision and smooth surfaces. Ideal for detailed prototypes and intricate designs.

DLP

DLP (Digital Light Processing) 3D printing is an additive manufacturing method that employs a digital light projector to cure resin layer by layer, producing highly detailed, precise objects swiftly.

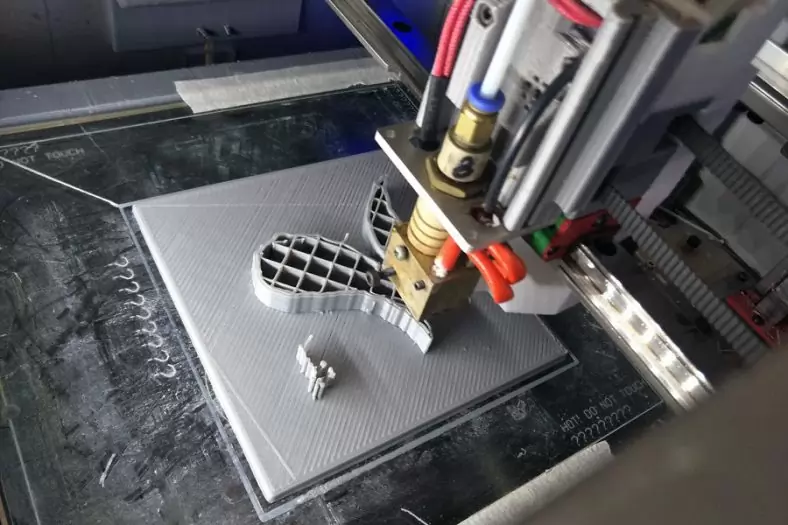

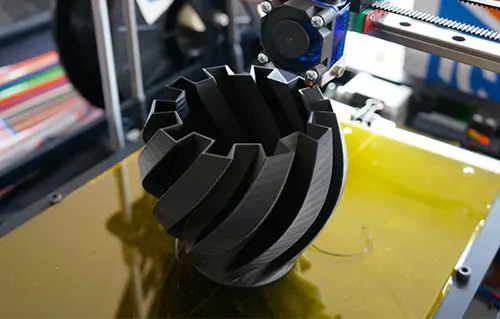

FDM

Perfect for rapid prototyping of thermoplastic parts. Able to deliver high-precision parts within 1 day.

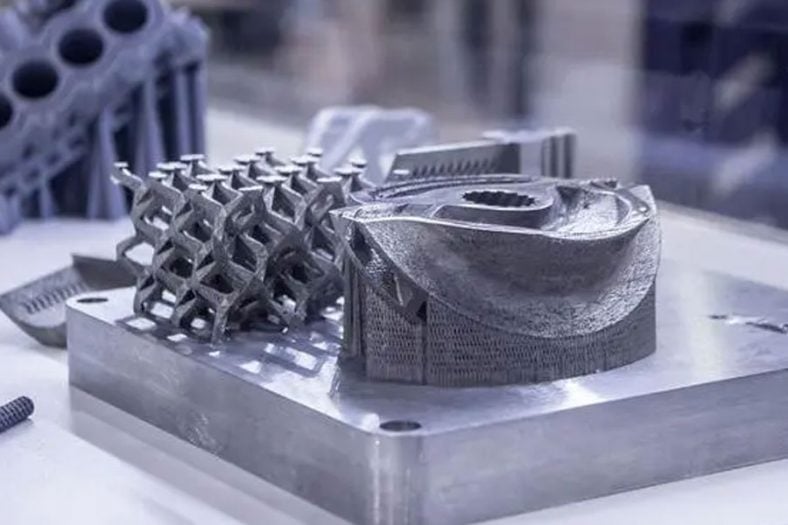

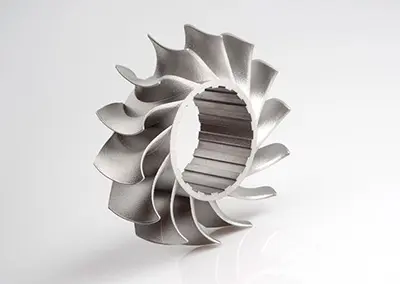

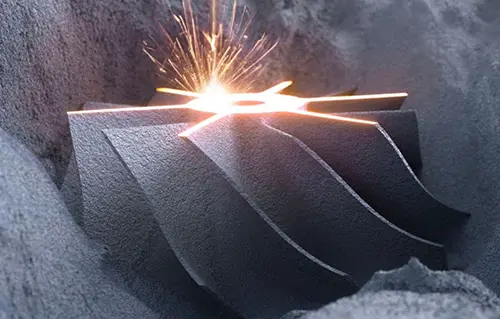

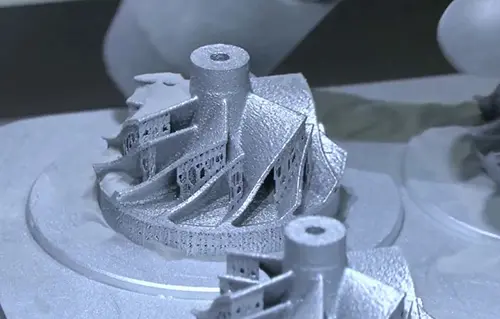

SLM

SLM (Selective Laser Melting) 3D printing service utilizes high-powered lasers to fuse metal powders layer by layer, creating complex, highly precise parts.

3D Printing Materials Selection

| Processes | DMLS | PolyJet | FDM | MJF | SLA | SLS | DLS |

|---|---|---|---|---|---|---|---|

| Available Materials |

Stainless Steel Hardened Steel Aluminum Titanium Copper |

Elastomer (30A to 95A) |

Nylon PETG PEI ASA ABS TPU PC |

Nylon |

Nylon Polypropylene TPU |

ABS Polycarbonate Polypropylene |

ABS Polypropylene |

| Max Part Size | 245 x 245 x 300 mm | 490 x 390 x 200 mm | 500 x 500 x 500 mm | 380 x 285 x 380 mm | 400 x 480 x 400 mm | 145 × 145 × 175 mm | 190 × 115 × 325 mm |

| Min Feature Size | 0.15 mm | 0.3 mm | 0.5 mm | 0.3 mm | 0.3 mm | 0.15 mm | 0.15 mm |

The Materials Of 3D Printing

| Thermoplastic Materials | ABS-M30, PC, POM-like, HDPE and other high-hardness, flame-retardant, high-temperature-resistant series production-grade thermoplastic materials. |

| Nylon | PA12 nylon series has the material properties of high strength and rigidity, high temperature resistance, chemical resistance, invariance, and excellent wear resistance. |

| Resin | Photosensitive resin is a kind of ABS-like white engineering plastic, which is easy for surface polishing and laser seamless stitching of super large objects. |

| Metal Material | Ti64 titanium alloy, MS1 mold steel, GP1 stainless steel, aluminum-magnesium alloy, cobalt-chromium alloy. |

| ABS | Similar to ABS white and red wax 3D printing materials, it is very suitable for manufacturing accurate, high-definition and ultra-fine details of models and prototypes. |

| Wax Material | Wax material has extremely high resolution and fine details, suitable for high-end lost wax casting of jewelry, clocks and micro-medical and electrical equipment |

DMLS/SLM/EBM process is the best choice for prototyping and rapid production of small and large metal parts. You receive high dimensional precision parts made from a wide choice of ‘right materials’:

Prototype and Parts Made Easy - Worldwide Delivery & Any Order Size

With many years of manufacturing experience, NPI offers the best solutions for all rapid prototyping and low to large volume manufacturing needs. We streamline the innovation cycle into four simple but effective steps.

01

Upload Your Design

02

Receive Design Analysis

03

Start Manufacruting

04

Receive Your Parts

More 3D Printing Capabilities

3D modeling plays a crucial role in the success of 3D printing across various industries, including cultural creativity, animation, healthcare, construction, manufacturing, and food. Before 3D printing can occur, a detailed 3D model must be created. This can be accomplished using a variety of design software that is compatible with the selected 3D printing technology. Once the model is complete, it should be exported or converted to STL format to ensure optimal printing results. Effective 3D modeling not only enhances precision and quality but also supports innovation in product development and prototyping.

3D modeling software primarily falls into two categories:

Artistic design and industrial product development.

The first category focuses on creative applications like decorative artwork, movie special effects, animation figures, dolls, and cultural projects.

The second category emphasizes industrial design and mechanical engineering, utilizing software for CAD and CAM processes. Notably, Rhion stands out for its versatility, effectively bridging both realms. It excels in creating intricate 3D models for industrial applications while also facilitating artistic pursuits, including cartoon design, special effects, and three-dimensional animations. This dual functionality makes Rhion a valuable asset for professionals across various industries.

Industrial product design heavily relies on sophisticated 3D modeling software, with well-known options including SketchUp, SolidWorks, Pro/ENGINEER (PROE), and Unigraphics (UG). These tools utilize parametric analysis to develop precise 3D models based on customizable design parameters.

- Blender: As an open-source, free 3D modeling software, Blender excels in functionality and is compatible with all major operating systems. It offers a comprehensive suite of tools for 3D creation, enabling rapid and efficient architectural designs while maintaining high-quality output.

- SketchUp: Developed by Google, SketchUp is a user-friendly, interactive 3D modeling application ideal for both beginners and experienced users. Its intuitive interface simplifies the modeling process, making it a preferred choice for those new to design.

- SolidWorks: Esteemed for its powerful capabilities, user-friendly interface, and technological innovations, SolidWorks stands out as a go-to tool for many engineers and designers, fostering creativity and efficiency.

- UG and PROE: Both UG and PROE are advanced CAD/CAE/CAM solutions tailored for the manufacturing sector. While UG is recognized for its unparalleled precision in surface modeling and complex industrial design,

3D modeling software enhances art design by allowing precise manipulation of points, lines, and surfaces, enabling the creation of intricate graphic structures. Notable tools include Maya for film animation, 3ds Max for architectural visualizations and entertainment, and Modo, a versatile platform featuring advanced modeling technology. Additionally, ZBrush excels in brush sculpting, offering powerful capabilities for detailed character design. These professional-grade applications ensure stunning visual displays and seamless transitions in 3D art, making them essential for artists and designers aiming for high-quality results in their projects.

Traditionally, doctors rely on two-dimensional CT scans to diagnose and treat conditions like liver tumors. However, interpreting these flat images requires physicians to mentally reconstruct complex three-dimensional (3D) representations based on their experience, a method that can lead to inaccuracies and misdiagnosis.

Advancements in 3D printing technology have transformed this process. By processing data from medical imaging techniques such as X-ray CT and MRI, professionals can convert these images into Computer-Aided Design (CAD) files suitable for 3D printing. The resulting 3D models not only replicate the spatial characteristics of the original images but also allow for tactile interaction with critical anatomical structures. This innovative approach enhances medical education, supports clinical practice, and facilitates scientific research.

Looking ahead, 3D printing technology promises to revolutionize various medical applications, including the creation of patient-specific medical models, artificial bones, prosthetics, and even bioprinting organs. This integration of advanced technology into healthcare will significantly improve diagnostic accuracy and treatment outcomes, ultimately benefiting patient care.

Introducing our advanced U-level high-resolution 3D scanner, imported from Germany, which boasts an exceptional accuracy of up to 0.007mm. This state-of-the-art scanner is capable of measuring a diverse range of objects, from intricate components as small as 38mm to large structures up to 2 meters, while maintaining impressive local resolution for objects as large as 30 meters.

Our scanner excels in a myriad of applications, including 3D scanning of toy figurines, artwork, Buddha statues, cultural relics, mud sculptures, ivory sculptures, mobile phones, and automobiles, as well as precision body scans. The device generates .stl data files for seamless integration with 3D printing and fine carving projects.

- Measuring point: 2×5000 000

- Measuring area: 38×29-2000x1500mm2

- Measuring point distance 0.01-0.62mm

Our advanced non-contact three-coordinate scanning system, imported from Germany, revolutionizes product measurement. Utilizing cutting-edge blue light technology and a precision resolution of up to 16 million pixels, this equipment ensures high accuracy and efficiency, effectively eliminating errors in point cloud calculations. This technology is capable of generating precise .stl data files from extensive point data compilation.

Key features include:

- 3D Coordinate Conversion: Accurate calculations of spatial dimensions and three-dimensional shape deviations.

- Object Point Definition: Under quasi-static conditions, we can precisely define object coordinates and analyze three-dimensional displacement and deformation across various components.

- Comprehensive Quality Control: Our system conducts thorough assessments, including gap deformation, flatness testing, and component deformation analysis (CAV comparison).

This advanced scanning solution is tailored for high-end clients requiring meticulous product design and testing. It facilitates real-time detection of production process deviations, ultimately saving time and reducing costs while enhancing overall production efficiency.

In mold manufacturing, where iterative adjustments are essential, our scanning technology aids in reverse-engineering molds that meet specifications. By creating a digital model of the optimized mold, we can streamline the development of processing programs, significantly boosting mold production efficiency and minimizing expenses. Optimize your manufacturing processes with our state-of-the-art scanning solutions.

Reverse engineering is a sophisticated process that transforms existing physical products—such as prototypes, molds, or sculptures—into detailed CAD models. By leveraging advanced digital technologies and high-precision scanning systems, this technique captures even the most intricate geometric features, resulting in accurate, high-resolution 3D point cloud data. This data is essential for reconstructing complex surfaces in CAD software.

The benefits of reverse engineering are substantial; it accelerates the new product development cycle while minimizing costs, thereby enhancing a company’s capacity for independent product innovation. This approach is particularly advantageous for items with complex geometries and free-form surfaces, making it a vital component in industries such as manufacturing, automotive, and aerospace. Ultimately, reverse engineering not only streamlines design processes but also fosters creativity and efficiency in product development.

For more functions, please contact our salesperson to explain to you

Efficient 3D Printing for Diverse Industries

3D Printing FAQs

Join Us in Crafting Excellence Together

- All uploads are secure and confidential.